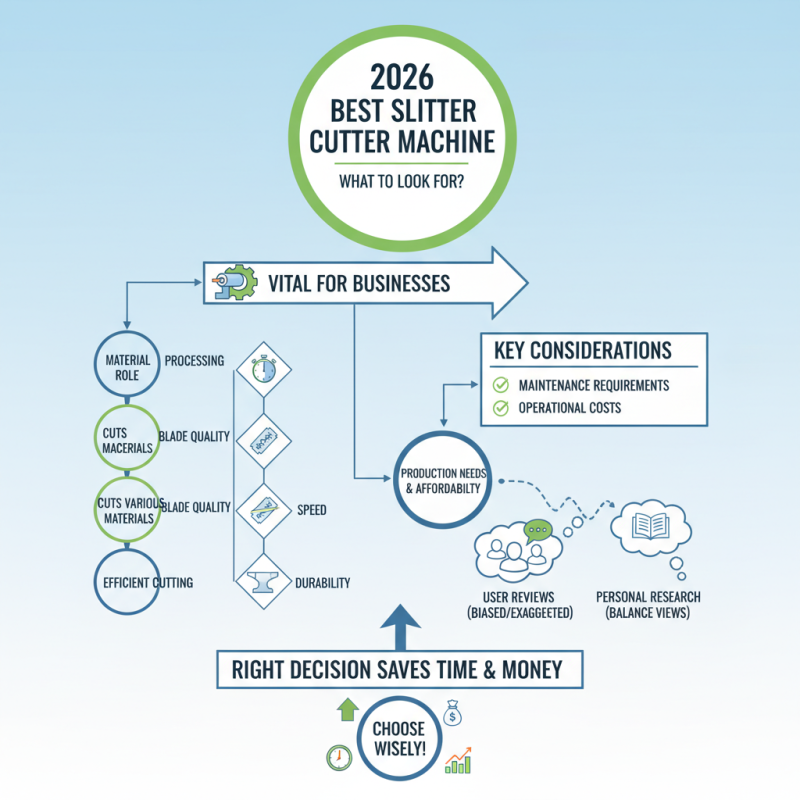

In 2026, choosing the right Slitter Cutter Machine is vital for businesses. This machine plays a crucial role in material processing. It helps in cutting a variety of materials efficiently. Factors such as speed, blade quality, and durability must be considered.

When exploring Slitter Cutter Machines, users often overlook specific details. For instance, the machine's maintenance requirements are essential for long-term use. Many buyers get caught up in features and forget about operational costs. Choosing a model that meets your production needs while being affordable is key.

User reviews can offer valuable insights. However, many opinions may be biased or exaggerated. It’s important to balance these views with personal research. The right decision will save time and money, impacting overall productivity. Invest time in understanding the options available. Reflect on your unique needs to choose wisely.

When selecting a slitter cutter machine, there are crucial features to consider. Precision is paramount. A machine that delivers consistent cuts ensures material waste is minimized. According to industry reports, precision slitting can reduce production waste by up to 25%. This means not just savings but also meeting strict quality standards.

Speed is another vital aspect. Modern machines can operate at impressive speeds, with some capable of cutting at rates exceeding 1,000 meters per minute. However, high speed isn't everything. A machine that compromises accuracy for speed can lead to increased errors, ultimately affecting production efficiency.

Additionally, user-friendliness can’t be overlooked. Operators must feel comfortable controlling the machine. Complicated setups can lead to frustration and delays. A user-friendly interface often improves workflow. Remember, investing in technology is not just about the initial purchase. It's about long-term efficiency and adaptability in changing market conditions. A balance of these features is essential for a successful operation.

When selecting a slitter cutter machine, the types of materials compatible with these machines play a crucial role. Industries often use slitter cutter machines for various materials such as paper, plastic, metal, and textiles. According to a report by Technavio, the demand for slitting machines in the paper industry is expected to flourish due to increased recycling operations.

Different materials require specific tuning for effective slitting. For example, paper tends to be more flexible and easier to cut. In contrast, metals require precise settings to avoid damage. The thickness of materials also affects slitting performance. It’s crucial to evaluate the characteristics of each material type when making a purchase.

Tip: Always conduct tests with your material before committing to a large-scale operation. Knowing how different materials behave will save time and reduce errors. Embrace the learning curve. Sometimes, adjustments in technique can lead to performance improvements.

Furthermore, the slitting process itself can vary by material. For instance, while plastics may fracture under stress, textiles might fray. Regular maintenance of the blade is essential for optimal results. It's common to overlook blade sharpness, but dull blades can lead to damaged materials.

Tip: Schedule routine checks on your equipment. A stitch in time can prevent bigger issues later. Remember, perfection is a journey, not a destination.

When it comes to slitting processes, precision and accuracy are crucial. A slight deviation can lead to waste and reduced quality. Slitter cutter machines must consistently deliver precise cuts. This results in better end products and less downtime. Operators must understand how small adjustments can improve overall effectiveness.

Tip: Regularly calibrate your machine. Calibration helps maintain accuracy. Skipping this step can lead to costly errors.

Another factor to consider is the material being processed. Different materials react uniquely to cutting tools. Take time to experiment with settings. Sometimes, even a minor change can enhance performance.

Tip: Keep an eye on blade wear. Dull blades can cause uneven cuts. Replace them promptly to maintain precision.

Understanding the balance between speed and accuracy is essential. Rushing can compromise quality. Always prioritize producing high-quality cuts over finishing quickly. Remember, a focus on precision will pay off in the long run.

Proper maintenance is vital for extending the lifespan of slitter cutter machines. Regular checks can prevent costly repairs. According to industry reports, companies can save up to 30% on operational costs through effective maintenance strategies. Scheduled maintenance, rather than reactive repairs, reduces downtime significantly.

Cleanliness plays a crucial role in machine longevity. Dust and debris buildup can lead to malfunctions. Ensure all parts, especially blades and rollers, are cleaned regularly. Lubrication is another essential factor. Insufficient lubrication can cause higher friction, leading to premature wear. Consistent checks on fluid levels can save time and resources down the line.

Operators should be trained to recognize early signs of potential issues. Vibrations, unusual noises, and inconsistent cutting quality are red flags. Addressing these problems swiftly can avert major breakdowns. Keeping a detailed maintenance log helps track performance and identify patterns. This data-driven approach is invaluable for optimizing machine use.

When evaluating the cost-effectiveness of slitter cutter machines, it's crucial to consider several factors. First, assess the machine’s initial cost. A lower price might seem appealing, but it could come with compromises in quality or durability. Look for features that enhance productivity. Machines that can handle various materials may provide better value over time.

Maintenance costs are another critical aspect. Some machines require frequent repairs, which can add to overall expenses. It's beneficial to choose a model designed for longevity. Additionally, consider energy consumption. A more efficient machine can lead to significant savings.

User feedback should also play a role in your decision. While promotional materials are attractive, real-world experiences provide insights. Seek reviews that detail both positive and negative aspects. This helps in understanding potential hidden costs. Balancing performance and budget is essential. It requires careful consideration and sometimes a willingness to compromise.

| Model | Blade Material | Cutting Width (mm) | Speed (m/min) | Power Consumption (kW) | Estimated Cost (USD) |

|---|---|---|---|---|---|

| Model A | High-Speed Steel | 1800 | 200 | 2.5 | 5000 |

| Model B | Carbide | 1600 | 180 | 2.2 | 6000 |

| Model C | Stainless Steel | 2000 | 220 | 3.0 | 5500 |

| Model D | Titanium Coated | 1900 | 210 | 2.7 | 6500 |

| Model E | Diamond Coated | 1700 | 230 | 2.0 | 7000 |