In the ever-evolving landscape of industrial automation, the choice of components plays a pivotal role in enhancing operational efficiency and performance. One such critical component is the Pneumatic Rotary Actuator, known for its versatility and reliable motion control. This blog explores seven innovative benefits of selecting the best Pneumatic Rotary Actuator, backed by compelling industry application cases that highlight its effectiveness in various settings. Whether you're looking to optimize an assembly line, improve material handling, or boost precision in robotic applications, understanding these advantages is essential. Furthermore, we will provide practical "how to" insights for integrating these actuators into your systems, ensuring that you harness their full potential to drive productivity and success. Join us as we delve into the transformative impact of Pneumatic Rotary Actuators across different industries.

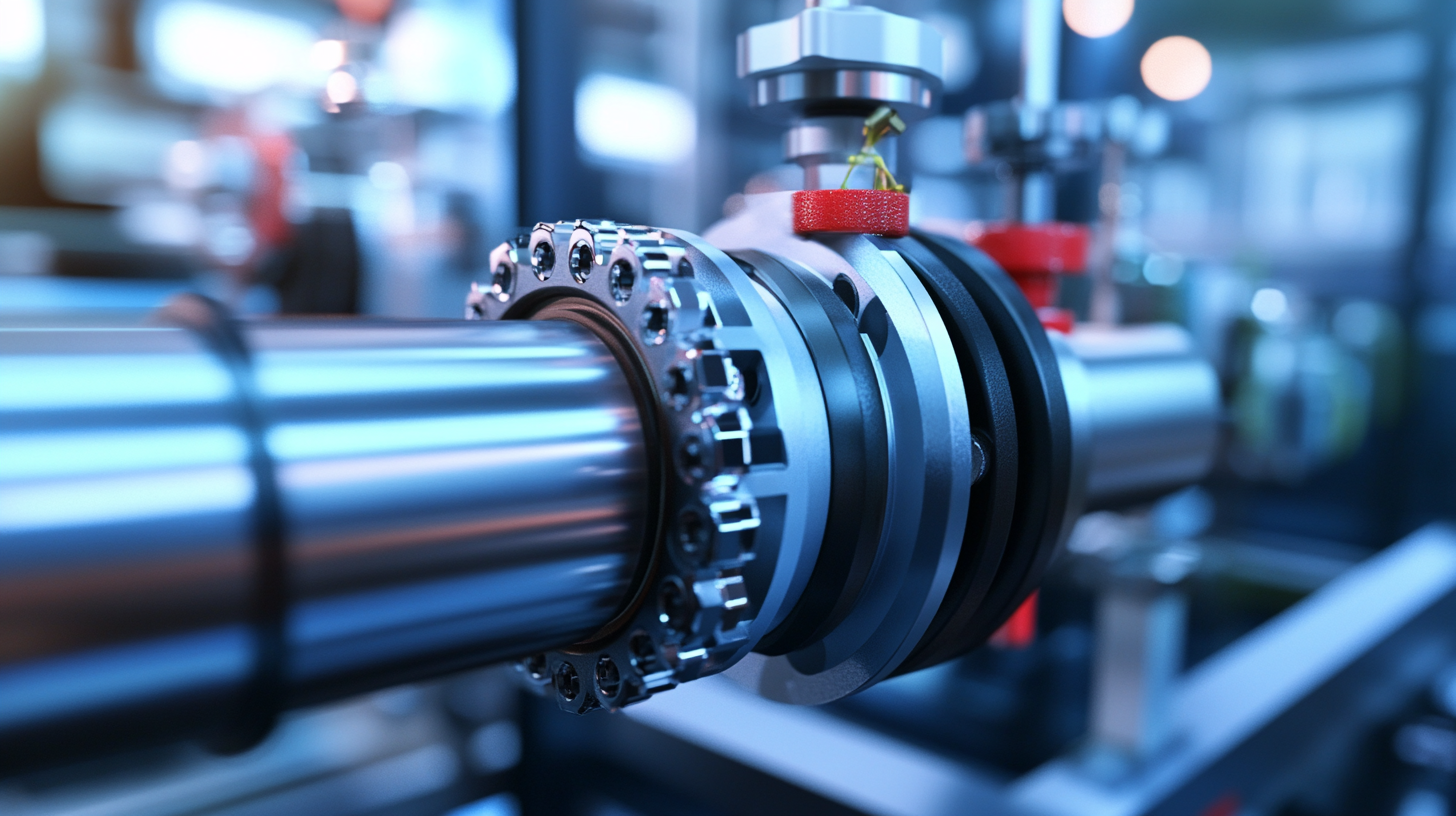

When considering the efficiency gains of top-quality pneumatic rotary actuators, it's essential to recognize their innovative benefits. These actuators excel in providing precise control and enhanced responsiveness, making them ideal for various industrial applications. Their ability to convert compressed air into rotary motion allows for smoother operations and improved cycle times, significantly boosting productivity.

One essential tip when selecting a pneumatic rotary actuator is to evaluate its compatibility with your existing systems. Ensure that the actuator’s specifications align with your application's requirements, such as torque output and rotation speed. Additionally, consider the actuator's durability and maintenance needs; a well-constructed actuator can lead to reduced downtime and lower operational costs.

Another consideration is the installation environment. High-quality pneumatic rotary actuators are designed to withstand challenging conditions, from extreme temperatures to exposure to chemicals. Choosing an actuator with the right environmental rating can prevent malfunction and extend the lifespan of your equipment. Remember, investing in the best pneumatic rotary actuators not only enhances performance but also contributes to a more efficient and cost-effective operational framework.

Pneumatic rotary actuators are transforming the landscape of industrial automation, providing unparalleled performance enhancements that can significantly benefit various applications. By employing compressed air as a power source, these actuators offer rapid response times and precise control, making them ideal for processes that require efficiency and accuracy. The advanced technology embedded in modern pneumatic rotary actuators allows for smoother operation, reducing wear and tear on both the actuator and associated machinery, leading to improved system longevity and reliability.

Pneumatic rotary actuators are transforming the landscape of industrial automation, providing unparalleled performance enhancements that can significantly benefit various applications. By employing compressed air as a power source, these actuators offer rapid response times and precise control, making them ideal for processes that require efficiency and accuracy. The advanced technology embedded in modern pneumatic rotary actuators allows for smoother operation, reducing wear and tear on both the actuator and associated machinery, leading to improved system longevity and reliability.

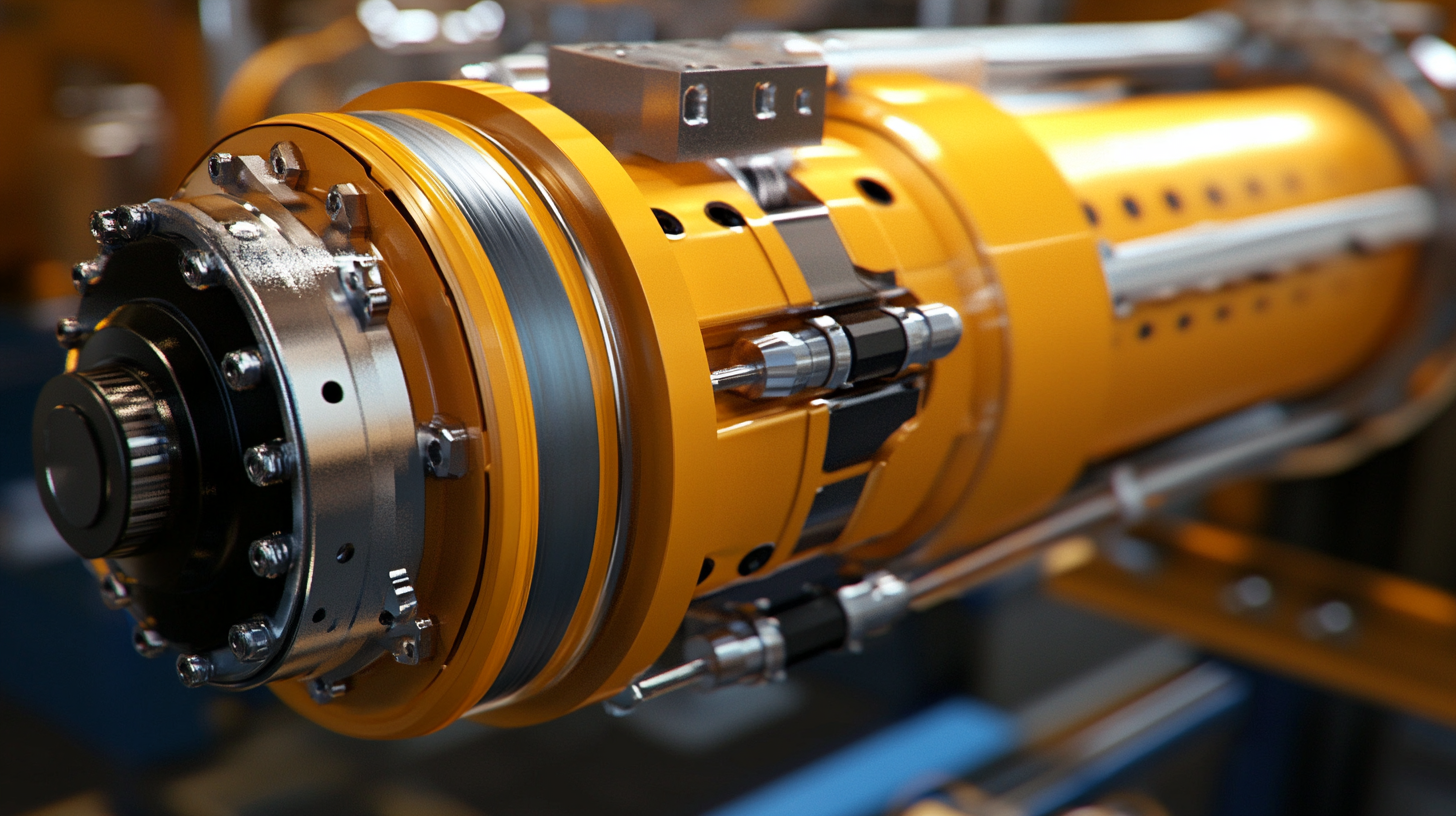

One of the most innovative benefits of using state-of-the-art pneumatic rotary actuators is their ability to integrate with advanced control systems. This enables seamless communication and coordination with other equipment in the production line, enhancing overall system performance. These actuators can be tailored for specific requirements, such as varying torque levels and rotation angles, leading to optimized workflows. Additionally, advancements in feedback mechanisms provide real-time monitoring, allowing for adaptive responses to changing operational conditions, ultimately driving productivity and minimizing downtime in industrial environments.

Selecting the right pneumatic rotary actuator can lead to significant cost savings for businesses. By investing in high-quality actuators that are specifically suited to their applications, companies can reduce maintenance costs and the frequency of replacements. This not only minimizes downtime but also ensures that operations run smoothly. When actuators are optimized for performance, they operate more efficiently, which subsequently lowers energy consumption and reduces utility bills over time.

Additionally, the right pneumatic rotary actuator can enhance productivity by increasing the speed and accuracy of various processes. When machinery works at peak efficiency, manufacturers can achieve higher output levels without incurring extra costs. Moreover, with improved reliability, there is less risk of unexpected failures, which can lead to unplanned expenses. As businesses continue to seek ways to optimize their operations, understanding the long-term financial benefits of using top-quality pneumatic rotary actuators becomes crucial in driving sustainable growth and profitability.

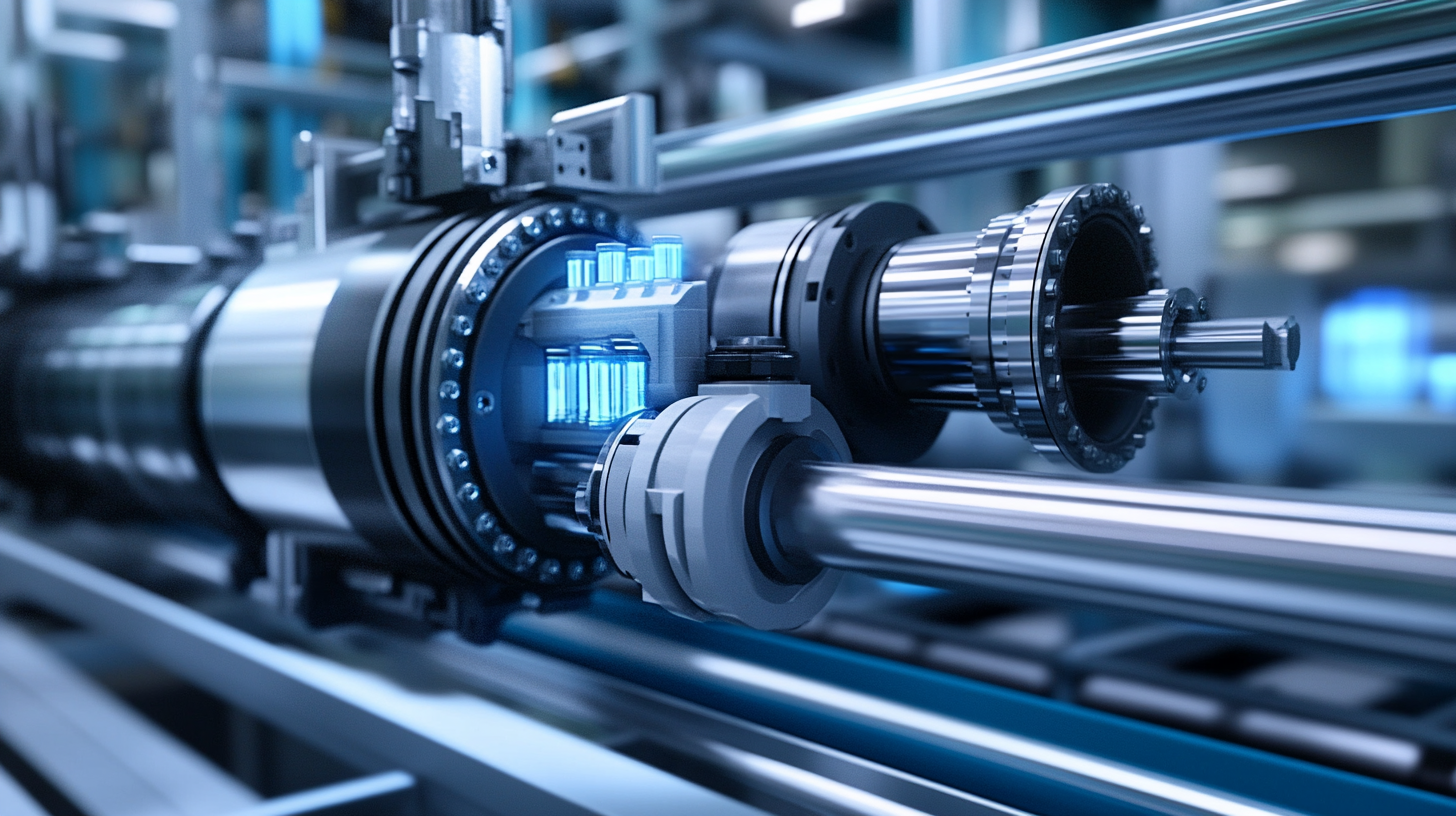

Pneumatic rotary actuators have emerged as critical components in enhancing precision and control across various industries. This innovation is underpinned by advancements in actuator technologies, which are pivotal for applications ranging from robotics to rehabilitation systems. For instance, research highlights adaptive digital twin models integrated with multilevel inverter control, which bolster energy efficiency in smart rehabilitation devices. This synergy between pneumatic actuation and digital modeling enhances operational accuracy, thus enabling more effective rehabilitation processes.

Moreover, the robotics actuators market is projected to grow significantly, with an expected compound annual growth rate (CAGR) of 8.9% by 2032. This growth is attributed to the demand for high-performance actuators that provide not only precision control but also adaptability in extreme environments. As industries increasingly adopt biomimetic design principles, innovations in pneumatic rotary actuators will likely play a crucial role, particularly in soft robotics. By mimicking natural biomechanics, these actuators are advancing the capabilities of devices designed for delicate operations, such as elbow joint rehabilitation, ultimately leading to better patient outcomes and greater operational efficiency.

| Benefit | Description | Application Examples |

|---|---|---|

| Improved Precision | Advanced control systems allow for accurate positioning and repeatability. | Robotics, automated assembly lines |

| Increased Efficiency | Faster operation speeds decrease cycle times. | Manufacturing plants, conveyor systems |

| Compact Design | Space-saving designs fit well into tight spaces. | Robotic arms, compact machines |

| Durability | Robust construction withstands harsh environments. | Food processing, manufacturing |

| Adaptability | Can be tailored for various applications and requirements. | Custom machinery, automation projects |

| Low Energy Consumption | Efficient operation reduces overall energy costs. | Continuous manufacturing processes |

| Safety Features | Incorporated safety measures prevent accidents and ensure reliability. | Heavy machinery, automated systems |

When it comes to industrial automation, safety is paramount. Investing in reliable pneumatic rotary actuators can significantly elevate safety standards within various operating environments. These actuators, known for their precision and efficiency, minimize the occurrence of unexpected failures, thereby reducing the risk of accidents. By ensuring seamless operation during critical processes, businesses not only protect their workforce but also preserve equipment integrity.

**Tip:** Regular maintenance checks on pneumatic rotary actuators can prevent potential mishaps. Routine inspections should focus on the seals, fittings, and connections to ensure that all components function optimally.

Moreover, the advanced technology behind pneumatic rotary actuators offers enhanced control and responsiveness. This capability enables operators to respond swiftly to changing conditions, further amplifying safety measures. The precise movement provided by these actuators allows for a more deliberate and controlled operation, crucial in high-stakes environments.

**Tip:** Implement training programs for staff on the proper use and monitoring of pneumatic rotary actuators. Well-informed operators can swiftly identify anomalies and take corrective action before issues escalate.