In today's fast-paced industrial environment, the importance of selecting the right components for automation cannot be overstated. Pneumatic cylinders, integral to a wide array of manufacturing and assembly processes, have been shown to enhance efficiency and precision in operations. According to a report by MarketsandMarkets, the global pneumatic cylinder market is projected to reach USD 7.51 billion by 2026, growing at a compound annual growth rate (CAGR) of 4.2%. This growth underscores the increasing reliance on pneumatic systems across various sectors, from automotive to packaging. Given their ability to convert compressed air into linear motion, investing in the best pneumatic cylinder not only streamlines workflows but also significantly optimizes productivity. This blog explores 15 compelling reasons why choosing the right pneumatic cylinder should be your top priority, ensuring your operations remain competitive and efficient in an ever-evolving marketplace.

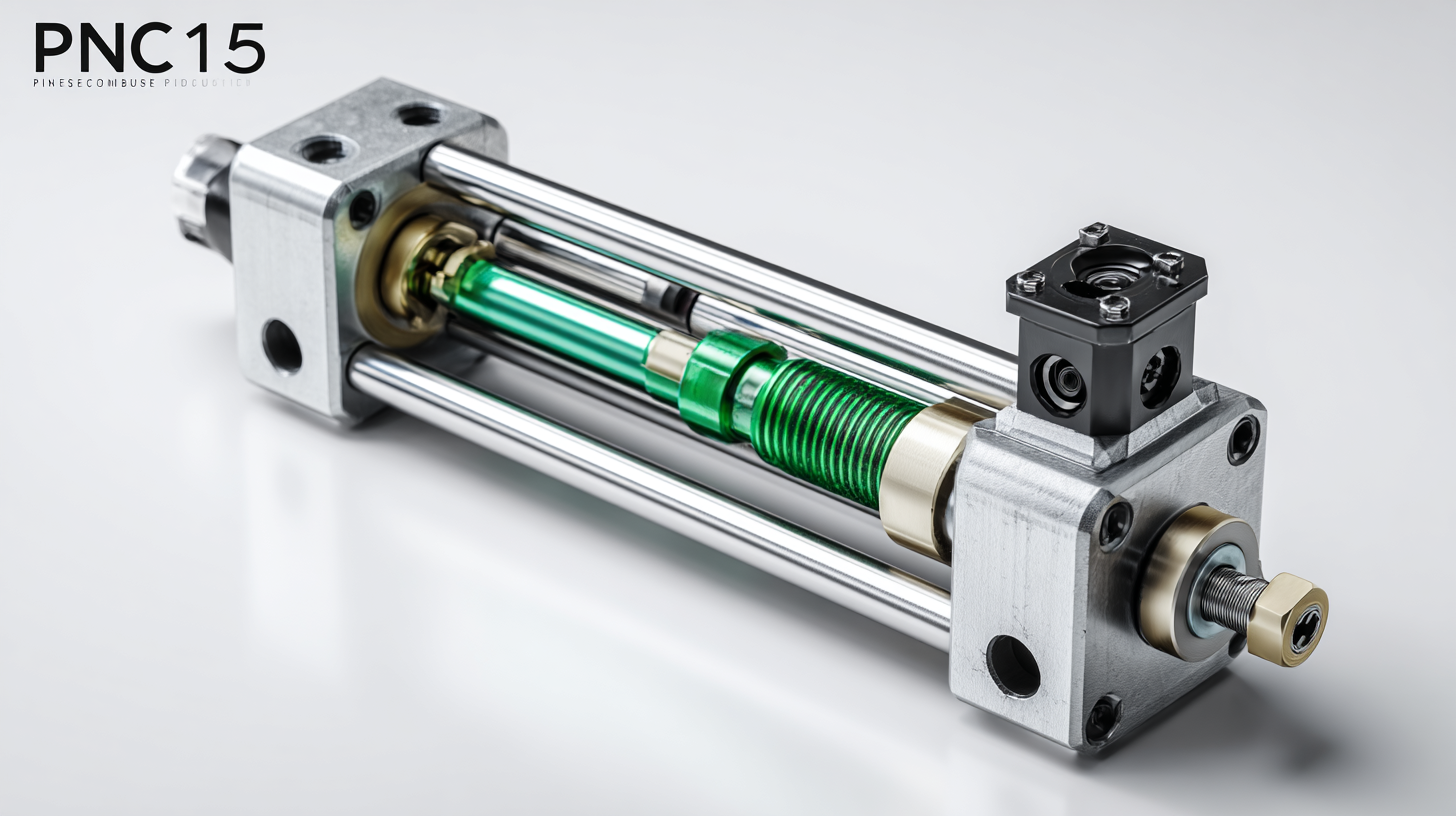

Pneumatic cylinders are revolutionizing the way automation processes are executed, providing both efficiency and precision that other systems often struggle to achieve. This is largely due to their ability to convert compressed air into mechanical energy, enabling rapid motion and consistent force application. The result? Increased productivity and a significant reduction in operational costs, making them an excellent choice for various industrial applications.

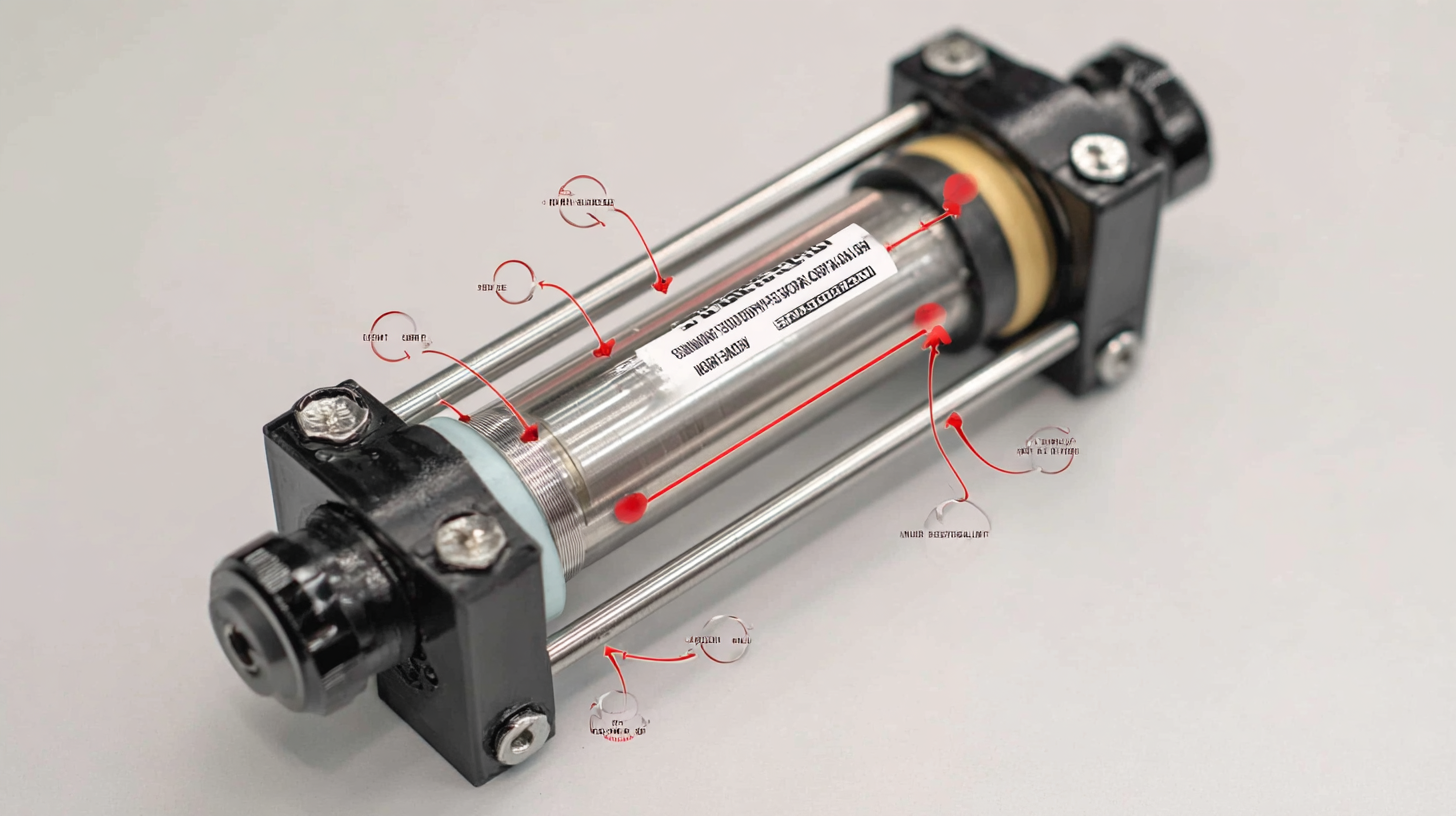

When considering pneumatic cylinders, it’s essential to ensure that you select the right size and capacity for your specific needs. Choosing a cylinder that is too small can lead to underperformance, while an oversized cylinder may waste energy. Additionally, investing in quality components can enhance reliability and reduce maintenance requirements. Regular inspections and maintenance can also extend the life of your cylinders, ensuring that they consistently deliver optimal performance.

To get the most out of pneumatic cylinders, it’s beneficial to automate the controlling systems. Implementing sensors and advanced control algorithms can help optimize the operation, ensuring that every movement is precisely timed and executed. Staying informed about the latest technologies and innovations in pneumatic systems can also provide ways to further enhance efficiency and performance in your operations.

When selecting the best pneumatic cylinder, understanding key factors is crucial for ensuring optimal performance in your applications. One of the primary considerations is the cylinder's design type, which significantly influences the efficiency and effectiveness of the operation. According to industry standards, ISO 15552 specifies dimensions for pneumatic cylinders, ensuring compatibility across various systems. This standardization enables smoother integration and greater reliability, making it an essential factor for users to consider.

Additionally, the materials used in the construction of pneumatic cylinders can directly impact their longevity and performance. A report from the International Journal of Advanced Manufacturing Technology highlights that cylinders made from high-strength aluminum and corrosion-resistant coatings exhibit a 30% increase in operational lifespan compared to standard materials. Users should also assess factors such as bore size, stroke length, and actuation type, as these parameters determine the suitability of a cylinder for specific tasks. By prioritizing these key factors, businesses can effectively choose pneumatic cylinders that meet their exact operational requirements and enhance productivity.

Pneumatic cylinders have emerged as a leading choice among industrial actuators, primarily due to their impressive performance metrics. According to a report by MarketsandMarkets, the global pneumatic actuators market is projected to reach $22.32 billion by 2026, underscoring the increasing demand for these efficient devices. One of the key advantages of pneumatic cylinders is their rapid cycle speed. They can achieve high speeds of up to 1 meter per second, making them ideal for applications requiring swift and precise movements. This responsiveness significantly contributes to increased productivity in manufacturing environments.

Moreover, pneumatic cylinders offer superior force-to-weight ratios compared to alternatives such as electric actuators. A study published in the Journal of Mechanical Engineering found that pneumatic systems can provide up to 10 times more force relative to their weight, translating into reduced structural support requirements and lower installation costs. Furthermore, their inherent simplicity and fewer moving parts result in less downtime and easier maintenance, making them a reliable choice for continuous operations. Overall, with industry reports consistently highlighting their advantages in speed, efficiency, and cost-effectiveness, pneumatic cylinders stand out as the top choice for modern automation needs.

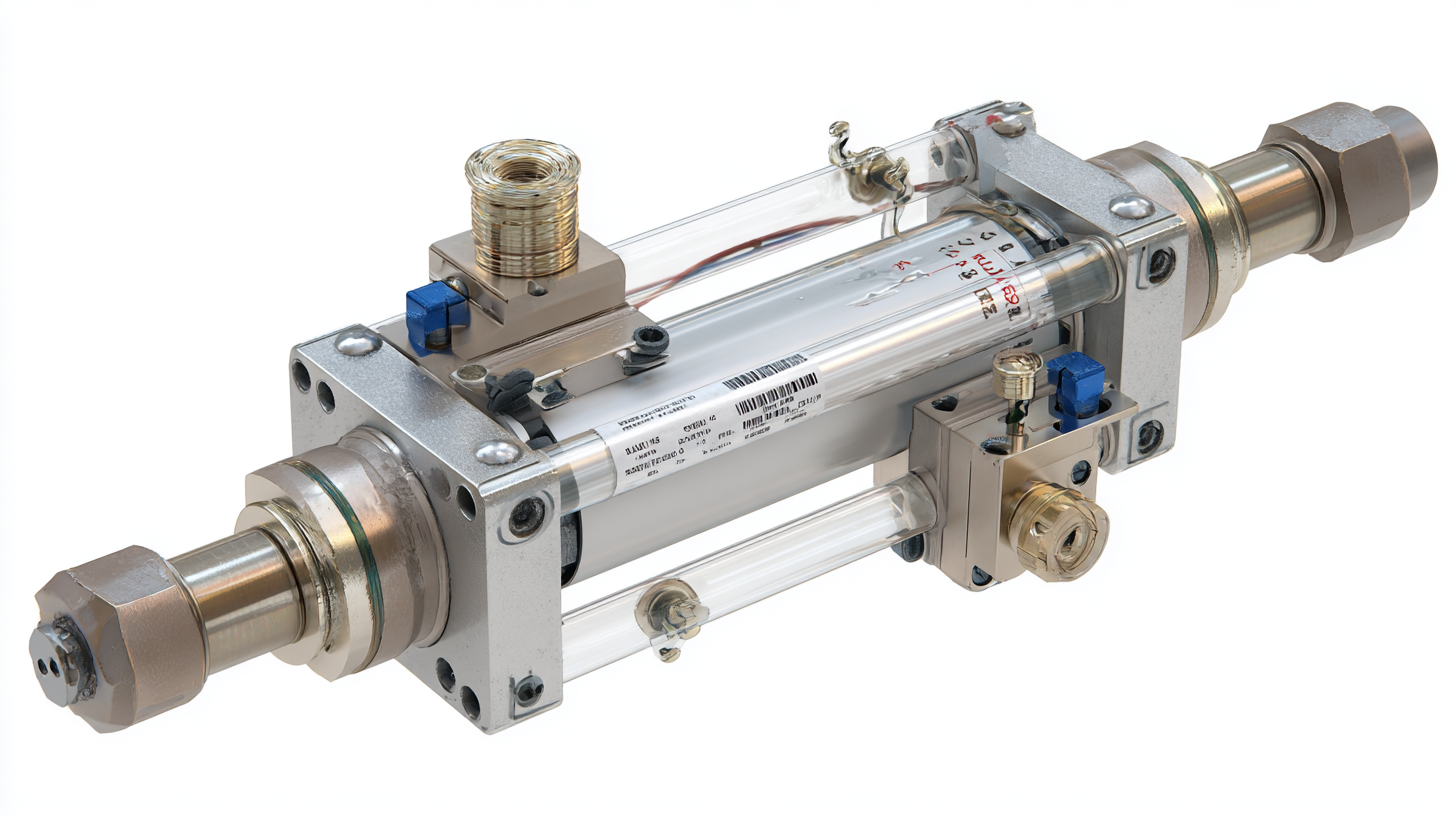

When considering the cost-effectiveness of pneumatic cylinders in industrial applications, one must appreciate how these components contribute to long-term savings. According to a report by the International Pneumatics Association, pneumatic systems can improve manufacturing efficiency by up to 30%, leading to significant reductions in operational costs. This efficiency stems from the rapid speed at which pneumatic cylinders act, allowing for quicker cycle times in production processes.

Moreover, pneumatic cylinders often require less maintenance compared to electric or hydraulic alternatives. The same report indicates that maintenance costs for pneumatic systems can be 20-50% lower over a five-year lifespan. This decreases downtime and enhances productivity, as businesses are not frequently halted for repairs. Additionally, when evaluating the total cost of ownership, pneumatic cylinders typically have a lower initial investment while delivering high performance, making them an ideal choice for many industrial applications. The combination of these factors ultimately leads to substantial long-term savings for companies looking to optimize their operations.

| Feature | Description | Potential Savings | Application Areas |

|---|---|---|---|

| Durability | High-quality materials ensure longer lifecycle. | Reduced replacement costs. | Manufacturing, Automotive |

| Energy Efficiency | Lower energy consumption compared to hydraulic systems. | Save up to 20% on energy bills. | Packaging, Material Handling |

| Low Maintenance | Requires less frequent servicing. | Savings on labor and maintenance parts. | Food Processing, Assembly Lines |

| Compact Design | Space-saving units fit in tight areas. | Maximized operational space. | Robotics, Automotive |

| Rapid Response | Immediate movement and control. | Increased throughput and productivity. | Manufacturing, Robotics |

| Safety Features | Built-in safety measures reduce accidents. | Lower insurance costs. | All industrial applications |

| Versatility | Can be used in various operations. | Less equipment needed for different tasks. | Manufacturing, Assembly, Logistics |

| Cost of Ownership | Lower overall costs over time. | Significant cost reductions in long run. | Wide range of industries |

The advancements in pneumatic cylinder technology have significantly influenced industry standards, positioning high-quality products as essential for modern applications. As industries evolve, the need for precision and efficiency has surged, compelling manufacturers to invest in innovative solutions. The integration of smart technologies, such as sensor-equipped pneumatic cylinders, enhances operational performance by providing real-time feedback and diagnostics, ultimately reducing downtime and maintenance costs.

In parallel, broader advancements in engineering, such as the development of lightweight composite materials and smart fluid power systems, are reshaping the landscape of pneumatic applications. These innovations not only improve the overall efficiency and reliability of pneumatic cylinders but also align with the growing emphasis on sustainability and energy efficiency across sectors. As companies aim to meet stringent environmental regulations and performance benchmarks, selecting the best pneumatic cylinder becomes crucial. It represents a convergence of cutting-edge technology and the industry's commitment to excellence, making it a top choice for businesses seeking to enhance their operational capabilities.