In the world of automation, Rotary Actuators play a crucial role in enhancing precision motion control across various industries. According to a recent report by MarketsandMarkets, the global rotary actuator market is projected to reach USD 8.1 billion by 2025, growing at a CAGR of 6.8% from 2020. This highlights the increasing reliance on advanced rotary actuator technology in applications from robotics to aerospace.

Evelyn Chen, a noted expert in automation technologies, states, "Precision in motion control can significantly boost overall system efficiency." This reflects the industry’s recognition of the importance of high-quality rotary actuators. However, challenges remain. Many manufacturers struggle with ensuring long-term durability and maintaining precise performance under varying loads. Design choices can greatly impact actuator effectiveness and reliability.

Evaluating the best Rotary Actuators involves considering not just the performance metrics but also the specific application requirements. Innovating in this space means addressing user feedback and adapting to emerging technologies. As the market evolves, the need for improved functionality and adaptability in rotary actuators becomes critical.

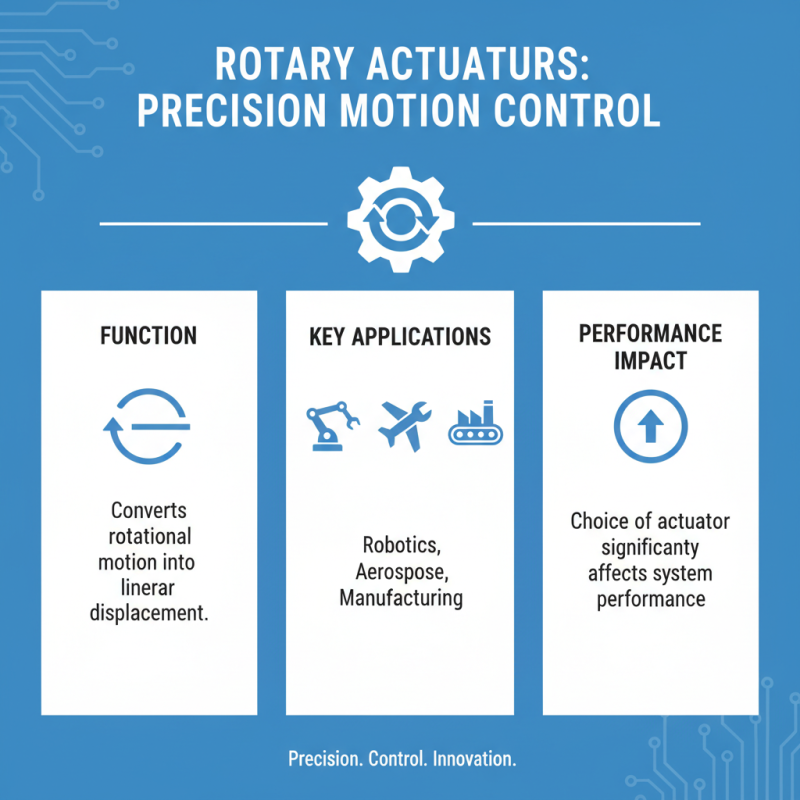

Rotary actuators play a vital role in precision motion control applications. These devices convert rotational motion into precise linear displacements. They are widely used in robotics, aerospace, and manufacturing. The choice of actuator impacts performance significantly.

In robotic arms, for example, rotary actuators enable smooth movement. They allow for intricate part assembly or manipulation. However, the selection process is not always straightforward. Factors such as load capacity and speed must be carefully considered. Achieving desired accuracy sometimes requires trial and error.

Another application is in aircraft control surfaces. Rotary actuators adjust flaps and rudders with precision. An optimal choice enhances fuel efficiency and safety. But, maintaining these systems can be challenging. Regular checks are necessary to prevent failures. It's a balance of performance and reliability that needs constant attention.

Rotary actuators are crucial in precise motion control. They are used in robotics, aerospace, and automation. Different types of rotary actuators have unique precision features. Understanding these types can help in choosing the right actuator for specific applications.

There are mainly three types: electric, hydraulic, and pneumatic actuators. Electric actuators offer accurate control with minimal wear. They excel in applications requiring consistent positioning. Hydraulic actuators provide high torque and can work in harsh environments. However, they may need frequent maintenance. Pneumatic actuators are fast and lightweight but can struggle with precision under load. Choosing the right actuator depends on the specific requirements of your project.

Sometimes, even the best actuator may fall short. Factors such as load variability and environmental conditions can impact performance. Regular testing and adjustments are necessary for optimal operation. It’s essential to evaluate not just the actuator’s specifications but also how it integrates into the overall system. A well-thought-out approach leads to better results.

When evaluating rotary actuators, performance metrics like torque, speed, and accuracy are crucial. Torque defines the actuator's ability to generate rotational force. Most high-performance models provide a torque range from 0.1 to 100 Nm. This variation caters to diverse applications, from robotics to aerospace. Keeping torque requirements in mind is vital. Misjudging them can lead to inadequate or excessive actuator use.

Speed is another key metric, often measured in revolutions per minute (RPM). Many actuators achieve speeds between 10 to 300 RPM. However, speed can impact accuracy. Faster speeds may lead to overshoot or oscillation in motion. A study showed that 15% of rotary systems faced significant inaccuracies during rapid movements. Slower speeds may improve precision but could hinder productivity.

Accuracy is often represented as a percentage, indicating the deviation from desired positions. High-end actuators boast accuracy within 1% of the target. Yet, achieving this level is often challenging due to mechanical wear and external factors. Some users report discrepancies up to 5% over time. Regular maintenance can help mitigate this, yet it's often overlooked.

Precision motion control is crucial in various industries. In manufacturing, accurate positioning is vital. Robotic arms rely on rotary actuators to move components precisely. These actuators help in assembling parts, welding, and painting tasks. Without proper motion control, production can suffer. Errors lead to waste and increased costs.

In medical applications, precision is even more critical. Surgical robots depend on actuators for delicate procedures. The margin for error is minimal. A slight miscalculation can result in severe consequences. Therefore, the technology behind rotary actuators must be reliable and accurate.

Aging infrastructure can present challenges. Some companies struggle to upgrade old systems. These outdated mechanisms may lack the accuracy needed. It forces engineers to reconsider solutions. Continuous improvements in actuator design are essential. They must adapt to new demands and enhance efficiency in diverse applications.

In the realm of precision motion control, rotary actuators play a vital role. They convert rotational motion into linear movement. This technology is crucial in robotics, aerospace, and manufacturing.

Recent advancements focus on miniaturization and enhanced torque. These innovations allow for greater customization in various applications.

Leading manufacturers are pushing boundaries in materials and design. Advanced sensors enhance feedback accuracy. This improvement leads to finer control, enabling complex maneuvers. However, the integration of these systems can be challenging. Compatibility with existing setups remains an area for improvement. Engineers need more flexible solutions that accommodate diverse environments.

Emerging trends include the use of smart technologies. This allows for real-time monitoring and adjustments. Yet, high costs can limit accessibility. The need for continuous research is evident. There is still room to optimize efficiency and performance. Innovative approaches will shape the future of rotary actuators.

Ultimately, balancing precision and cost is key.