In the realm of industrial applications, the selection of flow valves is crucial for ensuring operational efficiency and system reliability. According to a recent market research report by Allied Market Research, the global flow control valve market is projected to reach $11.8 billion by 2026, growing at a CAGR of 5.9% from 2019 to 2026. This growth underscores the importance of choosing the right flow valves, which play a pivotal role in regulating fluid flow and pressure within various systems. With numerous types of flow valves available—each designed for specific applications and conditions—understanding their functions, materials, and compatibility is essential. Failure to select the appropriate flow valves can lead to inefficient processes, increased energy consumption, and costly downtimes. Therefore, this guide aims to illuminate the key factors to consider when selecting flow valves tailored to your industrial needs, ensuring optimal performance and reliability.

In the realm of industrial applications, the selection of flow valves is crucial for ensuring operational efficiency and system reliability. According to a recent market research report by Allied Market Research, the global flow control valve market is projected to reach $11.8 billion by 2026, growing at a CAGR of 5.9% from 2019 to 2026. This growth underscores the importance of choosing the right flow valves, which play a pivotal role in regulating fluid flow and pressure within various systems. With numerous types of flow valves available—each designed for specific applications and conditions—understanding their functions, materials, and compatibility is essential. Failure to select the appropriate flow valves can lead to inefficient processes, increased energy consumption, and costly downtimes. Therefore, this guide aims to illuminate the key factors to consider when selecting flow valves tailored to your industrial needs, ensuring optimal performance and reliability.

When selecting flow valves for industrial applications, it's crucial to identify the specific requirements dictated by the application itself. For instance, the rising demand for accurate and contamination-free fluid transfer has highlighted the importance of precision flow control in various industries. According to recent market analyses, the peristaltic pumps market is thriving, driven by the necessity for automation and precision. Reports indicate that these pumps are experiencing substantial growth, as they offer reliable solutions for maintaining an uncontaminated environment in sensitive applications.

Additionally, compliance with regulations such as the FSMA and OSHA's recordkeeping requirements emphasizes the need for thorough documentation and tracking of fluid ingredients and transfers in industrial settings. These regulations not only protect workers and consumers but also demand that flow valves meet specific criteria to ensure safety and traceability. Industries must therefore assess the characteristics of the fluids they handle, such as viscosity, temperature, and pressure, to choose the right type of flow valve that safeguards operational efficiency and adheres to regulatory standards.

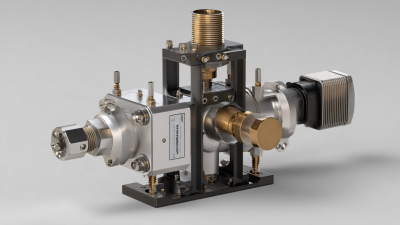

Flow valves are critical components in various industrial applications, and understanding the different types and their functions can significantly enhance system efficiency. There are primarily three types of flow valves: globe valves, ball valves, and gate valves. Globe valves are renowned for their ability to provide precise flow control, making them ideal for applications requiring throttling. According to a 2022 report from the Industrial Valve Market Analysis, the global market for globe valves is anticipated to grow at a CAGR of 4.6%, driven by increasing demand in water supply and wastewater treatment sectors.

Ball valves, known for their easy operation and low-pressure drop characteristics, are extensively used in on-off applications. Their design allows for a straightforward flow control mechanism, providing minimal turbulence. A study published by Research Dive in 2023 indicated that ball valves dominate the market due to their versatility and durability, comprising approximately 30% of the total valve sales in industrial sectors. In contrast, gate valves, often utilized in large pipeline systems for fully open or closed positions, play a crucial role in applications where the minimum pressure drop is vital, representing around 20% of valve installations.

Selecting the right flow valve involves assessing the specific requirements of the application, including pressure, temperature, and flow rate. Understanding the characteristics and advantages of these valve types enables engineers and operators to make informed decisions, optimizing the overall performance and safety of industrial processes.

| Valve Type | Function | Applications | Advantages |

|---|---|---|---|

| Ball Valve | On/Off control | Oil & Gas, Water Supply | Durable, low friction |

| Gate Valve | Isolation | Heating, Cooling Systems | Minimal pressure drop |

| Globe Valve | Flow regulation | Chemical Processing | Excellent throttling capabilities |

| Check Valve | Prevent backflow | Pumps, Pipeline Systems | Automatic operation |

| Butterfly Valve | Flow control | Water Treatment | Compact design, quick operation |

When selecting flow valves for industrial applications, evaluating material compatibility is crucial to ensure optimal performance and longevity. According to a report by the International Society of Automation (ISA), nearly 30% of valve failures are attributed to material incompatibility with fluids, leading to costly downtime and maintenance. For instance, using stainless steel valves in corrosive environments without considering the chemical composition can result in rapid degradation. Industries like chemical processing and oil and gas must thoroughly assess the compatibility of valve materials with the specific fluids they will encounter, including acids, bases, and hydrocarbons.

Environmental conditions also play a significant role in the selection of flow valves. The American Society of Mechanical Engineers (ASME) highlights that temperature fluctuations and exposure to moisture or dust can impact valve integrity. For example, valves designed for high-temperature applications often require specialized coatings to prevent thermal expansion issues. Moreover, in environments prone to extremes, such as cryogenic settings or high-pressure conditions, choosing the right valve material—such as PTFE or PEEK—can prevent leakage and ensure safety.

By meticulously evaluating both material compatibility and environmental conditions, industries can mitigate risks and enhance the reliability of their flow systems.

When selecting flow valves for industrial applications, two critical parameters are the flow rate capabilities and pressure ratings. According to a report by the International Society of Automation, valves must efficiently handle varying flow rates to ensure optimal process performance.

For instance, a valve designed with a high flow coefficient (Cv) can significantly affect the efficiency of fluid handling. Industries often require valves that can maintain a flow rate within a specified range, which might be between 10 to 100 GPM (gallons per minute) depending on the application. Choosing a valve with insufficient flow rate capabilities can lead to bottlenecks, whereas oversizing can cause instability in system performance.

Pressure ratings are equally crucial in valve selection. Valves must withstand specific pressures while ensuring safety and functionality. According to the American Society of Mechanical Engineers (ASME), many industrial processes operate under a pressure range of 150 to 600 psi. Utilizing valves with the correct pressure rating prevents failure or leaks in high-pressure systems. Proper evaluation of both flow rate capabilities and pressure ratings ensures that the chosen valve aligns with the operational demands, enhancing reliability and efficiency within industrial processes.

When choosing flow valves for industrial applications, cost efficiency and maintenance factors are key considerations. The selection of the right flow valve can significantly impact operational costs and ensure optimal performance. To achieve cost efficiency, it's crucial to evaluate the total cost of ownership rather than just the initial purchase price. This includes installation, operation, and maintenance costs over the valve's lifespan. Selecting durable materials and reliable designs can lead to savings by reducing the frequency of replacements.

Tip 1: Regular maintenance schedules should be established to ensure that flow valves operate efficiently. This prevents unexpected failures and prolongs the life of the equipment.

Tip 2: When assessing valves, consider their compatibility with the specific fluids and conditions of your application. Corrosion resistance and pressure ratings are vital in ensuring optimal performance and minimizing maintenance needs.

In today's rapidly evolving industrial landscape, investing in high-quality flow valves may require a higher initial expenditure but can lead to substantial long-term savings, thereby enhancing overall productivity and operational reliability.