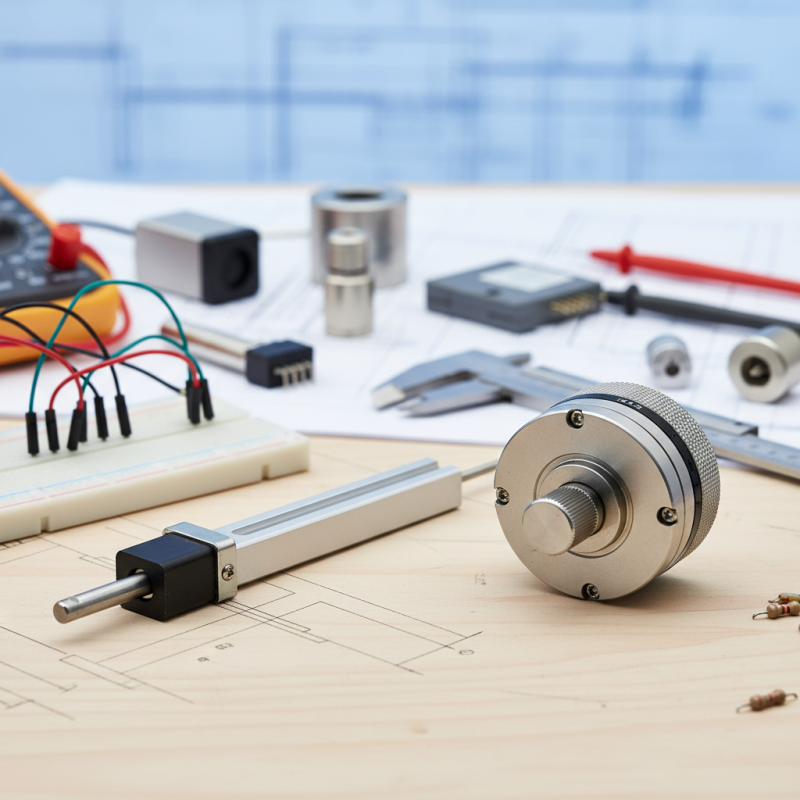

When working on a project, choosing the right Position Sensor is crucial for success. Position sensors track the location of objects. They can vary significantly in technology and application. It is important to understand your project needs before making a choice.

Consider the type of movements you want to measure. Are they linear or rotational? This will determine which position sensor suits you best. Sensors like potentiometers work well for linear motion, while encoders are more suitable for rotary movements. Each sensor type has its advantages and limitations.

Evaluating factors like accuracy, range, and environmental conditions is important. Some sensors may excel in controlled environments but fail in harsh conditions. Reflect on the sensor's performance in real-life scenarios. A seemingly good choice might not function as expected. Always remember that the right position sensor can make or break your project. Choose wisely.

When selecting a position sensor, it's crucial to understand the various types available today. Each sensor serves a unique purpose and excels in specific environments. For example, potentiometric sensors measure angular or linear positions using resistance change. They are simple and cost-effective but can wear out over time. Their reliability diminishes in harsh conditions, raising concerns about longevity.

Another popular option is inductive sensors. These non-contact devices are robust and often used in industrial applications. They detect metallic objects without physical contact, ensuring durability. However, they can be more expensive to implement. Their complexity might not be suitable for simpler projects. Then, there are optical position sensors, which use light to determine position. They are precise but sensitive to dust and dirt, which can result in inaccurate readings.

Understanding these distinctions is essential. Assess the specific requirements of your project. Think about the environment and the required accuracy. Selecting the right sensor is not just about preference; it's about suitability. Each option has its pros and cons, which may complicate your decision. Balancing these factors will guide you toward the best solution for your needs.

When selecting a position sensor for your project, start by considering key specifications. The measurement range is crucial. It defines how far the sensor can detect movement. Make sure it matches your application’s needs. Too narrow a range could limit functionality. A broader range may introduce complexity and increase costs.

Next, think about accuracy and resolution. Accuracy tells you how close the measurement is to the true value. Resolution indicates how finely the position can be measured. A high-resolution sensor may seem ideal but could lead to data overload. Striking a balance is crucial.

Finally, assess the environmental factors. Sensors have different tolerances to temperature, humidity, and vibration. Evaluate the location where the sensor will be used. A sensor performing well in one environment might fail in another. Pay attention to these details to avoid potential issues. Make sure to test under real conditions, not just theoretical ones. This will guide you toward a fitting choice.

When evaluating environmental conditions for position sensor applications, several factors come into play. Temperature extremes pose a significant risk. Sensors often operate within a small temperature range, generally between -40°C and 85°C. Exceeding these limits can lead to inaccurate readings or complete failure. A study highlighted that 30% of sensors failed due to improper temperature management in harsh conditions.

Humidity is another critical element. High humidity can cause corrosion or short circuits, jeopardizing sensor integrity. Reports show that 25% of sensor malfunctions result from moisture accumulation. For instance, deploying sensors in coastal regions requires robust enclosures to prevent failure from saltwater corrosion.

Additionally, vibration is often overlooked. In industrial settings, sensors can experience vibrations that affect their longevity and accuracy. Data indicates that 15% of sensor issues arise from unaccounted vibrations. It's vital to assess the mechanical stability of the mounting surface and the operational environment. Careful consideration of these environmental factors is crucial to ensure reliable sensor performance.

When selecting a position sensor for your project, understanding cost versus performance is crucial. According to industry reports, sensors with higher accuracy often come with a significant price tag. For instance, a high-resolution sensor can cost four times more than a lower-resolution model. This disparity makes it essential to assess your project's specific needs before making a decision.

Tips: Evaluate your accuracy requirements carefully. Sometimes, a lower-cost sensor can meet your needs without the premium features. Always weigh the trade-offs between performance and budget. Many projects prioritize basic functionality over high precision.

Additionally, consider the long-term implications of your choice. A cheaper sensor might save money now but could lead to higher maintenance costs later. Research indicates that 30% of projects faced delays due to sensor issues. Choosing wisely at the start can save time and resources down the line.

Tips: Test different sensors with a prototype first. Doing so can clarify which features are necessary. Remember, not every project demands state-of-the-art technology. Simple solutions can often provide the best results.

Choosing the right position sensor involves careful consideration of integration and compatibility. It’s important to match the sensor to your existing systems. Analyze how the sensor will interact with other components in your project. This includes checking communication protocols and electrical specifications.

Compatibility can be tricky. Sometimes, a sensor might meet performance specifications but fails to sync with your current architecture. This can lead to integration headaches. You might need to rethink aspects of your design if components do not mesh well.

Consider the adaptability of your existing systems. Old technology may limit your options. New sensors could offer advanced features but struggle with legacy systems. Seeking flexibility is key. Finding a balance between innovation and compatibility will enhance project success. Often, these decisions require iterative reflection and adjustment. Aim for solutions that fit seamlessly into your framework.

| Sensor Type | Measuring Range | Output Signal | Accuracy | Integration Compatibility |

|---|---|---|---|---|

| Potentiometer | 0 - 100 mm | Analog Voltage | ±1% | Easy integration with analog systems |

| Magnetic Sensor | 0 - 50 mm | Digital Signal | ±0.5 mm | Compatible with microcontrollers |

| Ultrasonic Sensor | 2 - 400 cm | Pulse Width Modulation | ±3 cm | Works with various interfaces |

| Laser Displacement Sensor | 0 - 10 m | Analog Voltage / Digital | ±0.01 mm | Compatible with high-precision systems |

| Capacitive Sensor | 0 - 5 mm | Analog Current / Voltage | ±0.5 mm | Good for moisture or non-contact applications |