Control valves play a crucial role in the management of fluid dynamics across various industries, ensuring that processes operate efficiently and safely. These devices are designed to regulate the flow, pressure, and temperature of fluids within a system, making them essential in applications ranging from chemical manufacturing to water treatment. Understanding how control valves function, their types, and their applications can significantly impact operational efficiency and safety. This article provides an insightful overview of control valves, exploring the fundamental principles that govern their operation, as well as practical tips for selecting and using them effectively. By delving into industry insights and best practices, we aim to equip readers with the knowledge needed to enhance their systems with the right control valves and optimize fluid management strategies.

Control valves play a crucial role in the management of fluid dynamics across various industries, ensuring that processes operate efficiently and safely. These devices are designed to regulate the flow, pressure, and temperature of fluids within a system, making them essential in applications ranging from chemical manufacturing to water treatment. Understanding how control valves function, their types, and their applications can significantly impact operational efficiency and safety. This article provides an insightful overview of control valves, exploring the fundamental principles that govern their operation, as well as practical tips for selecting and using them effectively. By delving into industry insights and best practices, we aim to equip readers with the knowledge needed to enhance their systems with the right control valves and optimize fluid management strategies.

Control valves are crucial components in fluid dynamics, designed to manage the flow and pressure of fluids within a system. By adjusting the area of the flow passage, control valves regulate the fluid flow rate, ensuring that systems operate efficiently and safely. According to the Global Control Valve Market report by MarketsandMarkets, the control valve market is expected to reach USD 10.5 billion by 2025, signifying its importance across various industries, including oil and gas, water treatment, and manufacturing.

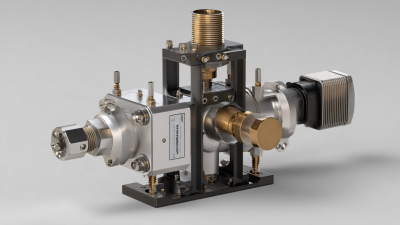

The basic functionality of a control valve involves the use of various actuator types to respond to signals from a controller. These actuators adjust the valve position based on the desired setpoint, facilitating precise control over fluid movement. This technology not only enhances operational efficiency but also plays a vital role in maintaining safety standards. A report from Research and Markets indicates that the adoption of smart control valves, integrated with IoT capabilities, is on the rise, projected to grow at a CAGR of 7.6% through 2024. This growth underscores the evolving nature of control valves, as industries increasingly seek advanced solutions for better monitoring and management of fluid processes.

| Dimension | Value |

|---|---|

| Type of Control Valve | Globe Valve |

| Functionality | Flow Regulation |

| Actuation Method | Pneumatic |

| Application Area | Oil & Gas |

| Temperature Range | -40°C to 150°C |

| Pressure Rating | Class 150 |

| Material | Stainless Steel |

| Control Method | Electronic |

| Common Issues | Leakage, Sticking |

| Maintenance Frequency | Annually |

Control valves are pivotal components in various industries, ensuring that fluids flow at the desired rates and pressures. Different types of control valves are suited to specific applications, each designed to handle unique challenges in fluid dynamics. Common types include globe valves, ball valves, butterfly valves, and check valves, each serving distinct roles. For instance, globe valves excel in precise flow regulation, while butterfly valves are ideal for larger flow rates due to their lightweight and compact design.

Control valves are pivotal components in various industries, ensuring that fluids flow at the desired rates and pressures. Different types of control valves are suited to specific applications, each designed to handle unique challenges in fluid dynamics. Common types include globe valves, ball valves, butterfly valves, and check valves, each serving distinct roles. For instance, globe valves excel in precise flow regulation, while butterfly valves are ideal for larger flow rates due to their lightweight and compact design.

Tip: When selecting a control valve, it’s crucial to consider the fluid type, operating conditions, and the specific requirements of your application. This attention to detail can significantly enhance efficiency and safety.

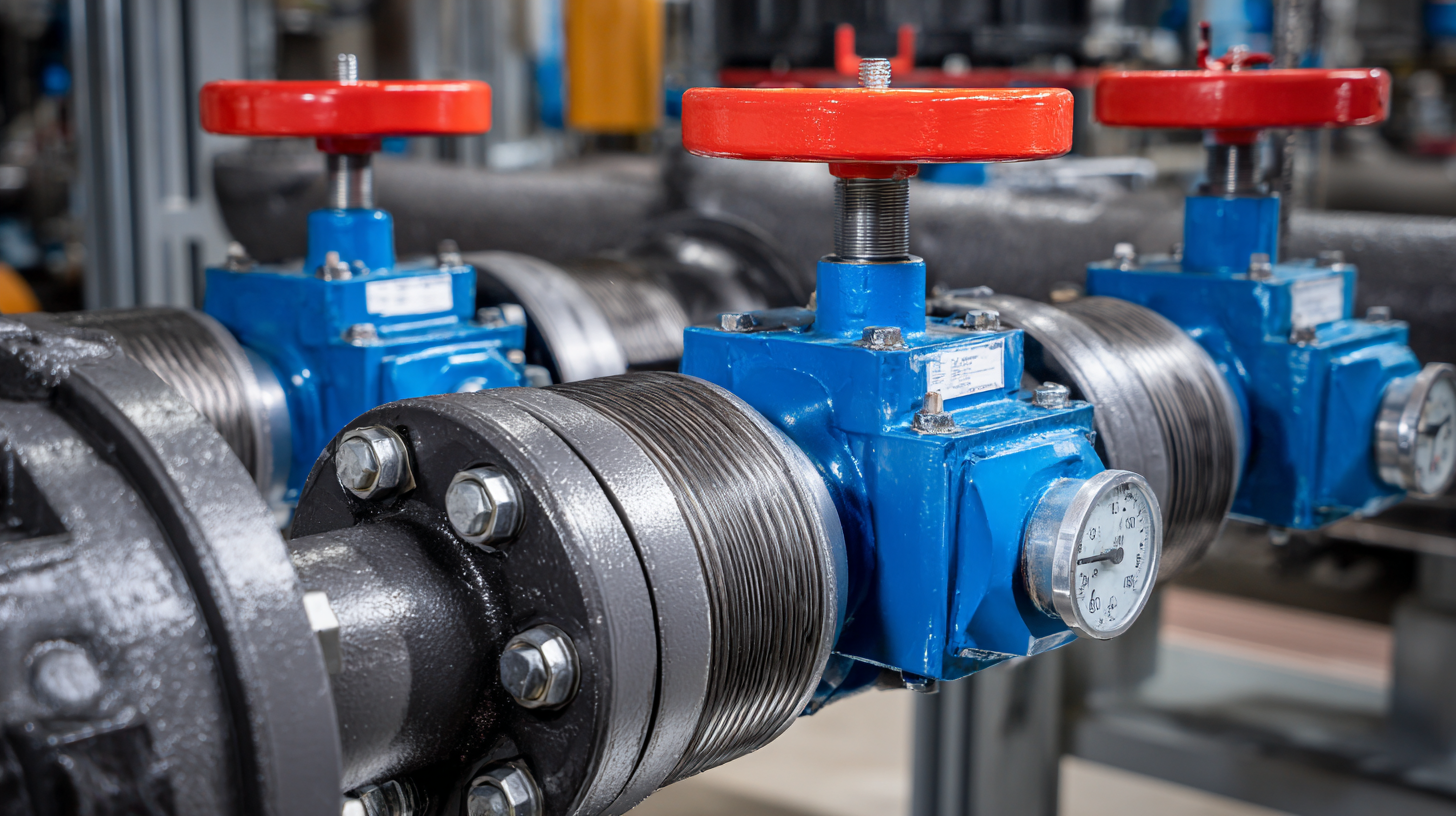

Industries such as oil and gas, water treatment, and chemical processing heavily rely on these valves. In oil and gas, ball valves are favored for their ability to provide a tight seal and secure shut-off capabilities. Conversely, the water treatment industry often employs butterfly valves due to their ability to handle large volumes of water with ease. By understanding the characteristics and applications of various control valves, engineers can better address the demands of their operational environments.

Tip: Regular maintenance and testing of control valves can prevent costly downtime and extend their lifespan, ensuring reliable performance in critical systems.

Control valves play a crucial role in fluid dynamics by regulating flow and pressure within systems, ensuring optimal performance and safety. Understanding the principles of fluid dynamics relevant to these valves is essential for effective design and application. The behavior of fluids—whether liquids or gases—can be greatly affected by factors such as viscosity, flow rate, and pressure differentials. Therefore, the selection and operation of a control valve must take these principles into account to achieve desired outcomes.

Tips: When choosing a control valve, consider the flow characteristics and the specific application environment. Utilize valves with a flow coefficient (Cv) that matches your system's requirements to ensure efficiency. Regular maintenance and testing can also prevent performance issues that may arise due to wear and tear over time.

Additionally, the position of the control valve within the system affects its performance. For instance, placing the valve too close to a pump can lead to cavitation, while positioning it too far may result in excessive pressure loss. Evaluating the entire fluid path allows for more effective use of control valves and maintains system integrity throughout operations.

Control valves play a crucial role in the regulation of fluid dynamics across various industries, facilitating optimal operational efficiency and safety. According to a recent report by MarketsandMarkets, the global control valve market was valued at approximately $7.91 billion in 2020 and is projected to reach $10.69 billion by 2025, growing at a CAGR of 6.5%. This growth can be attributed to increasing automation and advancements in control technologies, which are prevalent in sectors such as oil and gas, water management, and chemical processing.

Key applications of control valves encompass everything from regulating flow and pressure in pipelines to controlling temperature and level in industrial processes. For instance, in the oil and gas sector, control valves are integral for ensuring efficient flow regulation and safety during operations, especially as the industry continues to transform with smart technologies. In water treatment facilities, optimized control valve systems can lead to significant cost savings and improved environmental compliance.

Tip: When selecting control valves for your application, consider factors like response time and compatibility with specific fluids. It's also beneficial to consult with manufacturers for insights on the latest technologies and best practices to ensure optimal performance. Understanding the nuances of your application can result in a more efficient and reliable system.

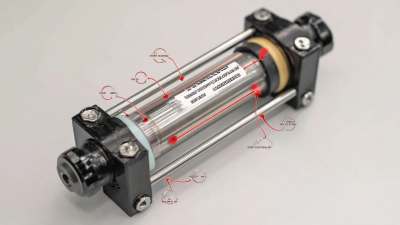

Control valves play a vital role in managing fluid flow within industrial systems, but their effectiveness largely depends on proper maintenance and prompt troubleshooting. A report from the International Society of Automation indicates that poorly maintained control valves can lead to a 20-30% increase in operational costs due to inefficiencies. Regular inspection, testing, and servicing can significantly enhance their reliability and performance, ultimately reducing the risk of unplanned shutdowns and ensuring operational continuity.

Troubleshooting control valves requires a systematic approach, beginning with identifying symptoms such as flow irregularities or excessive noise. According to the Control Valve Industry Association, approximately 70% of control valve failures are due to a lack of maintenance or incorrect installation. Implementing a proactive maintenance schedule, including calibration and replacement of worn parts, can mitigate such failures. Utilizing advanced diagnostic tools can also provide insight into valve performance, allowing operators to address issues before they escalate, thereby maintaining optimal fluid dynamics within the system.