The performance of control valves is critical in ensuring efficient operation across various industrial processes, yet organizations often face several challenges that hinder optimal performance. Understanding these challenges is essential for improving system reliability and efficiency. This blog will explore the key issues related to control valves, including wear and tear, improper sizing, and the impact of technology integration. We will also delve into the concept of "数字+Best", where digital solutions meet best practices to enhance valve performance and operational effectiveness. By addressing these performance challenges, industries can not only boost productivity but also reduce maintenance costs and downtime, paving the way for a more streamlined and effective process management approach. Ultimately, identifying and solving these issues is imperative for any organization that relies on control valves as a fundamental component of their operations.

Control valves play a crucial role in managing fluid flow in industrial processes, and understanding the various types is essential for optimizing their performance. There are several types of control valves, each designed to meet specific operational demands. For instance, globe valves are known for their excellent throttling capabilities, making them ideal for applications requiring precise flow control. Their design allows for effective regulation of flow, which is vital in processes where maintaining specific operating conditions is critical.

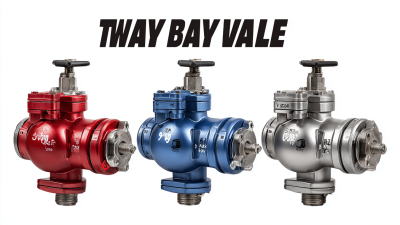

On the other hand, ball valves are favored for their quick operation and tight sealing properties. They provide an excellent solution for on/off control and are particularly beneficial in systems where pressure drops must be minimized. Additionally, butterfly valves offer lightweight and compact designs, making them suitable for large-scale applications where space and weight are factors. Understanding the unique benefits of each type of control valve allows engineers to select the right valve for their systems, ultimately leading to better performance and reliability in fluid control operations.

Control valves play a crucial role in regulating fluid flow in various industrial applications, but they face several performance challenges that can impact efficiency and productivity. One of the primary issues is valve wear and tear due to erosive or corrosive media. Over time, this wear can lead to reduced sealing effectiveness, increasing leakage and compromising flow control. The materials used in valve construction must be carefully selected to withstand the specific conditions of the process, otherwise, premature failure can occur.

Another significant challenge is the impact of temperature and pressure fluctuations on valve performance. Control valves must maintain accuracy and responsiveness under varying conditions, but thermal expansion and pressure spikes can cause hysteresis or excessive overshoot in flow control. Additionally, valve sizing is critical; improperly sized valves can lead to cavitation or instability in the control loop. Regular maintenance and smart design approaches, such as the use of advanced materials and technologies, can help mitigate these issues, ensuring optimal control valve operation and extending their lifespan in demanding industrial environments.

Optimizing control valve selection is crucial for enhancing operational efficiency in industrial processes. Control valves play a pivotal role in regulating flow, pressure, and temperature within systems, and their performance directly influences the overall productivity and safety of operations. By carefully selecting the right control valves, companies can minimize energy loss, reduce maintenance costs, and improve process reliability. This means assessing factors such as valve type, size, and materials, which can all impact the system’s response time and accuracy.

Furthermore, the benefits of an optimized control valve selection extend beyond immediate cost savings. Improved valve performance leads to better process control, resulting in enhanced product quality and consistency. For instance, in applications requiring precise flow rates, the right control valves can ensure that the desired parameters are maintained, reducing the likelihood of deviations that could affect product output. Consequently, investing in the appropriate control valves not only streamlines operations but also supports long-term sustainability and profitability.

In the realm of control valves, performance challenges can significantly hinder system efficiency and reliability. To tackle these limitations, various innovative strategies have emerged. For instance, advancements in electro-hydraulic valve-timing systems enable precise control over air and combustion dynamics, optimizing performance on a cylinder-by-cylinder basis. Such technologies allow for a tailored approach to enhance control valve functionality, ultimately leading to improved operational outcomes.

Moreover, the development of optimized flow rate control methods offers a promising direction for overcoming performance barriers in hybrid systems. By employing clustering-based regression models, engineers can fine-tune the flow dynamics in systems that integrate photovoltaic and heat pump technologies. This level of refinement not only boosts efficiency but also supports sustainability efforts in energy usage. Emphasizing these cutting-edge control strategies will help pave the way for more robust and effective control valve operations across various industries.

The future of control valve technology is poised for significant advancements, driven by both the increasing demand for automation and the integration of digital solutions. Innovations in materials such as PTFE linings will enhance performance and longevity, directly addressing the challenges facing control valves in various industries. PTFE-lined valves are projected to reach a market value of $64.14 million by 2024, increasing to $84.01 million by 2032, indicating a steady growth rate of 3.4%. This growth signifies a broader trend towards enhancing the reliability and efficiency of valve systems.

As the industry evolves, electrification stands out as a crucial theme. Companies are showcasing innovative solutions that facilitate this transition. One such example is seen in the developments presented at the 2025 Shanghai Auto Show, illustrating a push towards more sustainable and high-performance components for fluid management in automotive applications. Leveraging advanced technologies will not only improve control valve functionality but also integrate seamlessly with smart systems, leading to enhanced automated operations.

**Tips:** When considering control valve options, look for those with cutting-edge materials that promise durability and resistance to corrosion. Additionally, prioritize valves that offer compatibility with automation systems, as they provide better control and efficiency in various applications. Staying informed about emerging technologies in valve performance will enable businesses to remain competitive in a rapidly changing market.

| Performance Issue | Impact on Operation | Future Trends | Enhancement Strategies |

|---|---|---|---|

| Stiction | Causes erratic flow control, leads to instability | Smart valve technology integration | Use of anti-stiction coatings |

| Wear and Tear | Decreases reliability, increases maintenance costs | Advanced materials development | Regular inspection and predictive maintenance |

| Flow Characteristic Deviations | Affects accuracy and performance in process control | Adaptive control systems | Calibration and tuning of valves |

| Temperature Variations | Can lead to material failure or reduced efficiency | Thermal management technologies | Insulation and cooling systems |

| Control Algorithm Limitations | Ineffective response to process disturbances | AI and machine learning integration | Regular updates and training of control algorithms |