In today's fast-paced manufacturing and automation landscape, the efficiency and reliability of Pneumatic Cylinders are paramount for optimizing operational performance. According to a report by the International Federation of Robotics, the adoption rate of automation in manufacturing processes has surged by over 30% in the past five years, with Pneumatic Cylinders playing a crucial role in this transition. These devices, responsible for converting compressed air into mechanical motion, directly influence productivity, energy consumption, and overall equipment effectiveness (OEE). Industry experts suggest that performance optimization of Pneumatic Cylinders could lead to a reduction of up to 15% in energy costs and an increase in cycle times by 20%, making it essential for manufacturers to embrace advanced strategies aimed at enhancing their performance. This blog aims to explore the top strategies that can be employed to maximize the efficiency and longevity of Pneumatic Cylinders in various applications.

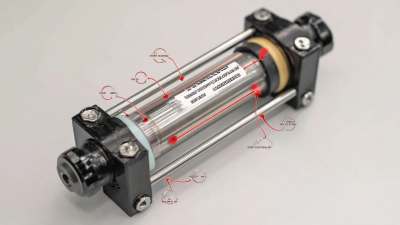

Pneumatic cylinders are critical components in various industrial applications, and their efficiency and longevity are influenced by several key factors. One of the most significant aspects is regular maintenance, particularly of tubing and fittings. Proper upkeep ensures that these parts function optimally, preventing leaks and pressure loss that could lead to inefficient operation. SMC emphasizes this point; routine checks and replacements of these components are essential for maintaining the overall health of pneumatic systems.

Moreover, selecting the right specifications for pneumatic cylinders based on operational requirements can greatly improve performance. Factors such as load capacity, stroke length, and the type of actuator play pivotal roles in how effectively a cylinder performs. Understanding the specific conditions under which the pneumatic system operates—including temperature fluctuations and potential exposure to contaminants—can significantly enhance operational longevity.

The careful consideration of these aspects can lead to improved efficiency, reduced downtime, and ultimately, a more sustainable approach to industrial automation.

Routine maintenance and regular checks are vital for ensuring the optimal performance of pneumatic cylinders. According to a report by the International Fluid Power Society, nearly 30% of pneumatic system failures can be attributed to inadequate maintenance practices. Implementing a structured maintenance schedule can significantly reduce downtime and extend the lifespan of your pneumatic components.

Tip: Conduct visual inspections at least once a month. Look for signs of wear, leaks, or unusual noises, which could indicate potential problems. Be sure to check connections and seals, as these are common failure points. Utilizing advanced monitoring systems can also provide real-time feedback on cylinder performance, allowing for proactive maintenance before issues escalate.

Furthermore, lubrication is key to keeping pneumatic cylinders operating efficiently. The American Society of Mechanical Engineers (ASME) recommends using the appropriate lubricant according to the manufacturer's specifications and ensuring it is applied correctly. Over-lubrication can attract contaminants, while under-lubrication can lead to excessive wear and tear on cylinder components.

Tip: Set up a lubricant application schedule based on operating conditions. If a cylinder operates in a harsh environment, increase the frequency of lubrication checks to prevent potential failures. Regularly replacing filters in the pneumatic system also helps maintain clean airflow, which is essential for peak cylinder performance.

Proper sizing of pneumatic cylinders is crucial to optimizing their performance, as it directly impacts factors such as efficiency, power output, and longevity. Ensuring that the cylinder bore is honed to the correct specifications allows for an optimal fit with piston rings, significantly enhancing the cylinder’s sealing capabilities and reducing friction. According to industry benchmarks, a well-honed cylinder can increase the performance of pneumatic systems by up to 15%, enabling smoother operations and less energy loss.

Furthermore, selecting the right pneumatic cylinder size ensures that it operates within its intended pressure and stroke length, maximizing both power and responsiveness. Research indicates that cylinders operating at their ideal ratios can improve the overall system efficiency by 20-30%. This alignment prevents common issues related to overloading or inefficiencies that arise when improperly sized components are used, ultimately leading to reduced maintenance costs and prolonged service life. Companies dedicated to optimizing cylinder performance are consistently examining new honing technologies and techniques to ensure that these components remain at the forefront of industrial performance standards.

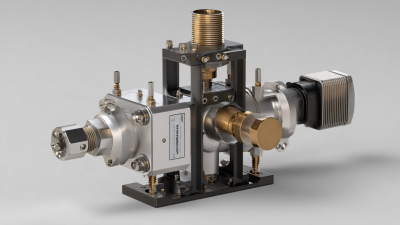

In the quest for optimizing pneumatic cylinder performance, innovations in materials and design play a pivotal role. Advanced materials, such as high-strength composites and lightweight alloys, have revolutionized the manufacturing of pneumatic cylinders. These materials not only reduce the overall weight of the cylinders but also enhance their durability and resistance to environmental factors. For instance, using corrosion-resistant materials can significantly extend the life of the cylinders in harsh industrial conditions, minimizing downtime and maintenance costs.

Moreover, innovative design features are crucial for maximizing functionality. The integration of smart technology, such as sensors and IoT connectivity, allows for real-time monitoring of performance metrics. This enables predictive maintenance strategies, reducing unexpected failures. Additionally, streamlined designs that minimize friction and optimize airflow can lead to improved efficiency and response times. As manufacturers continue to embrace these innovations, the potential for enhanced pneumatic cylinder performance becomes increasingly attainable, paving the way for more efficient and reliable automated systems in various industries.

Pneumatic systems play a vital role in various industrial applications, and ensuring optimal performance of pneumatic cylinders is essential for maximizing output. Common issues such as air leakage, improper pressure settings, and inadequate lubrication can hinder the efficiency of these systems. One of the first steps in troubleshooting is to regularly inspect all connection points for any signs of wear or damage. By identifying and sealing air leaks promptly, you can significantly improve system responsiveness and reduce energy consumption.

Another critical area to examine is the pressure settings. Frequently, systems operate below optimal pressure levels due to incorrect regulator settings or blockages in the lines. Regularly calibrating and adjusting the pressure to match the specific requirements of the application can help maintain consistent performance. Additionally, ensuring that pneumatic cylinders are adequately lubricated prevents excessive friction and wear, prolonging the life of the components. Implementing a routine maintenance schedule that includes checking lubricants, adjusting pressures, and inspecting for leaks will not only enhance performance but also prevent costly downtimes.

| Issue | Description | Solution | Performance Impact |

|---|---|---|---|

| Air Leakage | Loss of air pressure due to leaks in fittings or seals. | Inspect and replace faulty seals or fittings; use thread sealant. | Can reduce efficiency by up to 30%. |

| Cylinder Misalignment | Improper installation leading to uneven wear and performance. | Realign the cylinder to ensure proper operation. | May cause 15-25% reduction in speed and force. |

| Contaminated Air Supply | Dust, oil, or moisture in the air can affect cylinder performance. | Install air filters and regularly maintain the air supply system. | Can lower output efficiency significantly if not addressed. |

| Improper Lubrication | Inadequate or excessive lubrication can cause wear and performance issues. | Regularly check lubrication levels and adjust as needed. | Could impact lifespan and efficiency up to 40%. |

| Temperature Fluctuations | Extreme temperatures can affect the performance of pneumatic cylinders. | Use heat shields and ensure the system operates within recommended temperature ranges. | Temperature extremes can lead to performance drops of 20% or more. |