In the realm of industrial automation, the demand for precision and efficiency has never been higher, leading to the increased use of various components that can enhance operational capabilities. One such component that plays a pivotal role in this sector is the Pneumatic Rotary Actuator. This device is instrumental in converting compressed air into rotational motion, enabling seamless control of machinery and equipment. The significance of the Pneumatic Rotary Actuator transcends its basic function; it contributes to the overall efficiency, reliability, and safety of automated processes. By understanding the intricacies of this technology, industries can optimize their workflows and adapt to the evolving demands of modern manufacturing. In this discussion, we will delve into what a Pneumatic Rotary Actuator is, how it operates, and why it is indispensable for achieving superior performance in industrial applications.

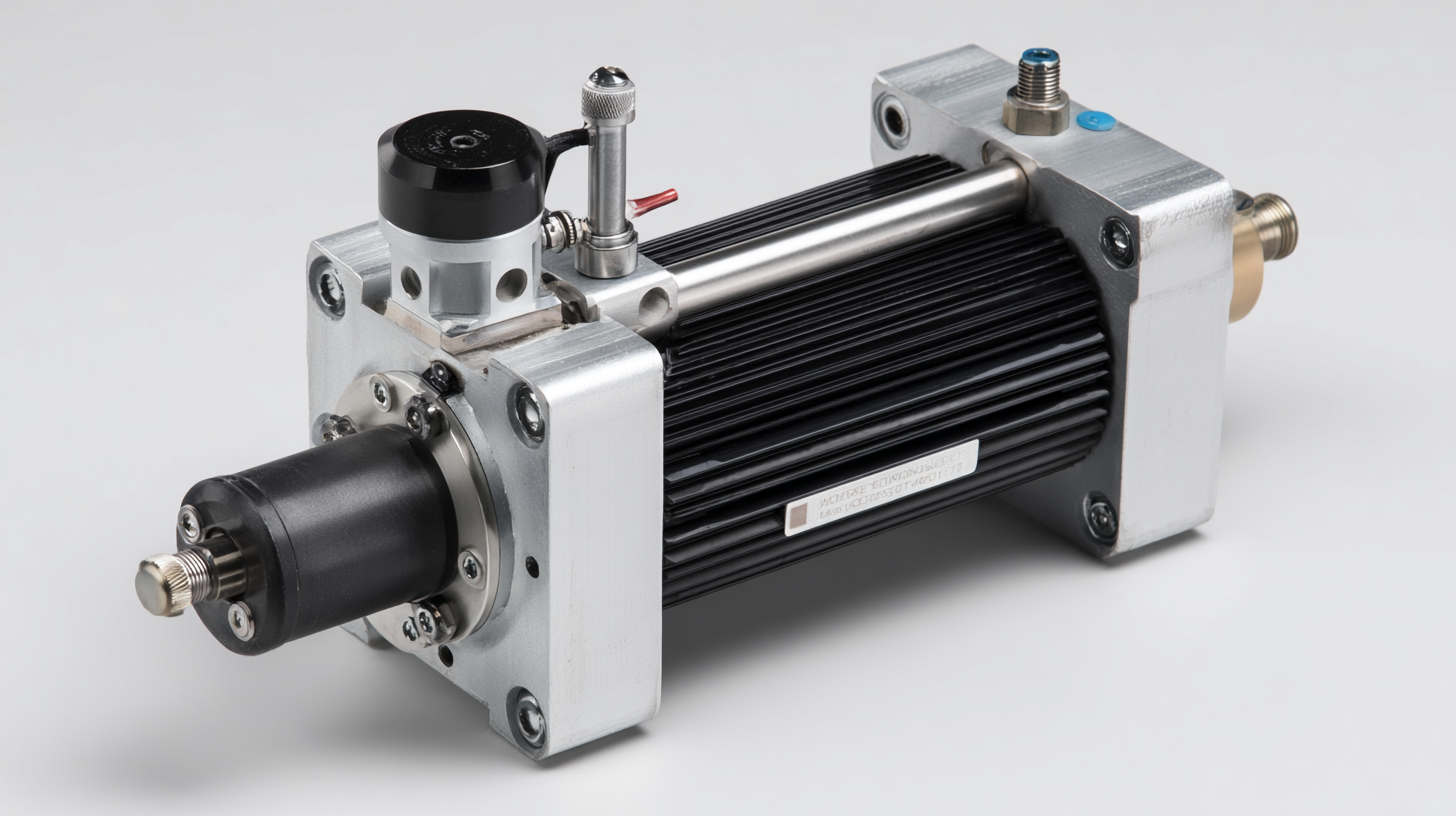

Pneumatic rotary actuators are critical components in industrial automation, providing precise control and efficient power transmission. These devices convert compressed air energy into rotary motion through the utilization of a simple yet effective mechanism. Typically, a rotating drum or vane translates the linear force of pressurized air into rotation, allowing for the initiation and termination of various automated processes. According to a report by MarketsandMarkets, the global pneumatic actuator market is projected to reach $10.45 billion by 2025, highlighting the growing significance of these actuators in enhancing operational efficiency across industries.

Tip: When selecting a pneumatic rotary actuator, it’s essential to consider factors such as torque requirements, rotational speed, and environmental conditions. This will ensure optimal performance and longevity of the actuator in your automation systems.

These actuators are renowned for their speed and reliability, making them ideal for applications like valve control, packaging, and assembly lines. With advancements in materials and technology, modern pneumatic rotary actuators now offer improved response times and reduced maintenance needs. A study from Research and Markets indicates that innovations in actuator technology could lead to a 15% increase in energy efficiency, a significant factor for companies aiming to reduce operational costs.

Tip: Regular maintenance and monitoring of pneumatic systems are vital for sustaining efficient actuator performance and preventing unexpected downtime.

| Feature | Description | Application | Advantages |

|---|---|---|---|

| Definition | A device that converts compressed air energy into rotational motion. | Material handling, valve actuation, and automated assembly. | High torque output, rapid response time, and simplicity of design. |

| Mechanism | Utilizes pneumatic pressure to rotate a shaft, often with gears or cams. | Used in robotics and automated systems. | Durability and minimal maintenance requirements. |

| Types | Single-acting and double-acting actuators, rack and pinion or vane-type. | Industry-specific applications like packaging or process control. | Versatile, energy-efficient, and capable of high-speed operations. |

| Control | Can be automated or operated manually with controllers and sensors. | Integration in smart factory systems for enhanced productivity. | Improves process reliability and allows precise motion control. |

Pneumatic rotary actuators play a crucial role in various industrial automation processes, providing reliable and efficient motion control. One key application is in the packaging industry, where these actuators are used to operate conveyor belts, control lid capping, and manage the filling process. Their ability to generate high torque with minimal air consumption makes them ideal for tasks that require precision and speed, significantly enhancing production efficiency.

Another significant application is in the automotive industry, where pneumatic rotary actuators enable robotic arms to perform tasks such as welding, painting, and assembly line operations. These actuators facilitate smooth and rapid movements, allowing for increased throughput and improved quality control. Additionally, they are employed in the food and beverage sector for automatic sorting, mixing, and filling, ensuring a high level of hygiene and consistency in processes. Overall, the versatility and reliability of pneumatic rotary actuators make them indispensable in modern industrial automation.

Pneumatic rotary actuators are increasingly favored in industrial automation due to their numerous advantages over other actuation methods. One of the primary benefits is their rapid response time. When compressed air is introduced, these actuators can achieve swift rotational movement, which is crucial for applications requiring quick adjustments or repetitive motions. This efficiency enhances productivity on the factory floor, allowing for faster cycle times in manufacturing processes.

Another significant advantage of pneumatic rotary actuators is their robustness and reliability. Unlike electric actuators, which may be sensitive to environmental conditions such as humidity and temperature, pneumatic systems are less affected by these factors, making them suitable for a variety of industrial environments. Additionally, pneumatic actuators typically have fewer moving parts than their electric counterparts, which reduces the likelihood of mechanical failure and maintenance requirements. This durability not only ensures continuous operation but also leads to cost savings in the long run, appealing to businesses looking to optimize their automation systems.

Pneumatic rotary actuators are vital components in industrial automation, facilitating precise movement and control in various applications. However, maintaining these actuators poses several challenges, as they are susceptible to wear, air leaks, and contamination. Effective maintenance strategies must address these issues to ensure optimal performance and prolonged service life. According to industry reports, the global actuator market is projected to reach USD 154.98 billion by 2033, highlighting the increasing reliance on actuators like pneumatic rotary models in automation processes.

To mitigate maintenance difficulties, regular inspections and the implementation of predictive maintenance techniques are essential. Utilizing advanced monitoring systems can help detect early signs of failure. Additionally, proper lubrication and the use of quality filters can significantly reduce contamination risks.

**Tips:**

1. Implement a scheduled maintenance program to regularly check for leaks and replace worn components.

2. Invest in high-quality filtration systems to preserve air quality and reduce wear on pneumatic components.

Maintaining pneumatic rotary actuators not only improves efficiency but also enhances the overall reliability of automation systems within the industrial sector.

The future of pneumatic rotary actuators is poised for significant advancements, driven by emerging technologies that enhance performance and efficiency in industrial automation. One notable trend is the integration of smart technologies, such as IoT-enabled sensors that monitor the actuator's performance in real-time. This capability allows for predictive maintenance, vastly reducing downtime and operational costs. Additionally, advancements in materials science are leading to lighter, more durable components that improve speed and responsiveness, paving the way for more complex automation solutions.

Tips: When considering the implementation of pneumatic rotary actuators in your operations, it's critical to assess the compatibility of new technologies with your existing systems. This ensures a smoother transition and maximizes the potential benefits of smart actuators.

Moreover, the focus on sustainability is pushing manufacturers to develop eco-friendly pneumatic rotary actuators. Innovations include the use of biodegradable lubricants and energy-efficient designs that minimize power consumption. As industries become more environmentally conscious, these developments will play a vital role in shaping a greener future for automation.

Tips: Stay updated on eco-friendly innovations by following industry publications and attending trade shows. Engaging with suppliers who prioritize sustainability can also provide insights into the latest technological advancements.