In the ever-evolving landscape of industrial automation, the significance of high-quality pneumatic valve actuators cannot be overstated. As industries around the globe strive for greater efficiency and reliability, many are turning to China's leading manufacturers, renowned for delivering unmatched quality in this essential component. With a commitment to innovation and excellence, these manufacturers have positioned themselves as trusted suppliers not only in China but across the world. The integration of advanced technology and robust engineering processes leads to pneumatic valve actuators that exhibit superior performance and durability. This blog explores the vital role of these devices in modern industrial operations and highlights how China's manufacturing prowess sets a benchmark for global quality standards in the field of pneumatic valve actuation.

Join us as we delve into the impressive capabilities and global trust in these remarkable products, affirming China’s status as a leader in manufacturing excellence.

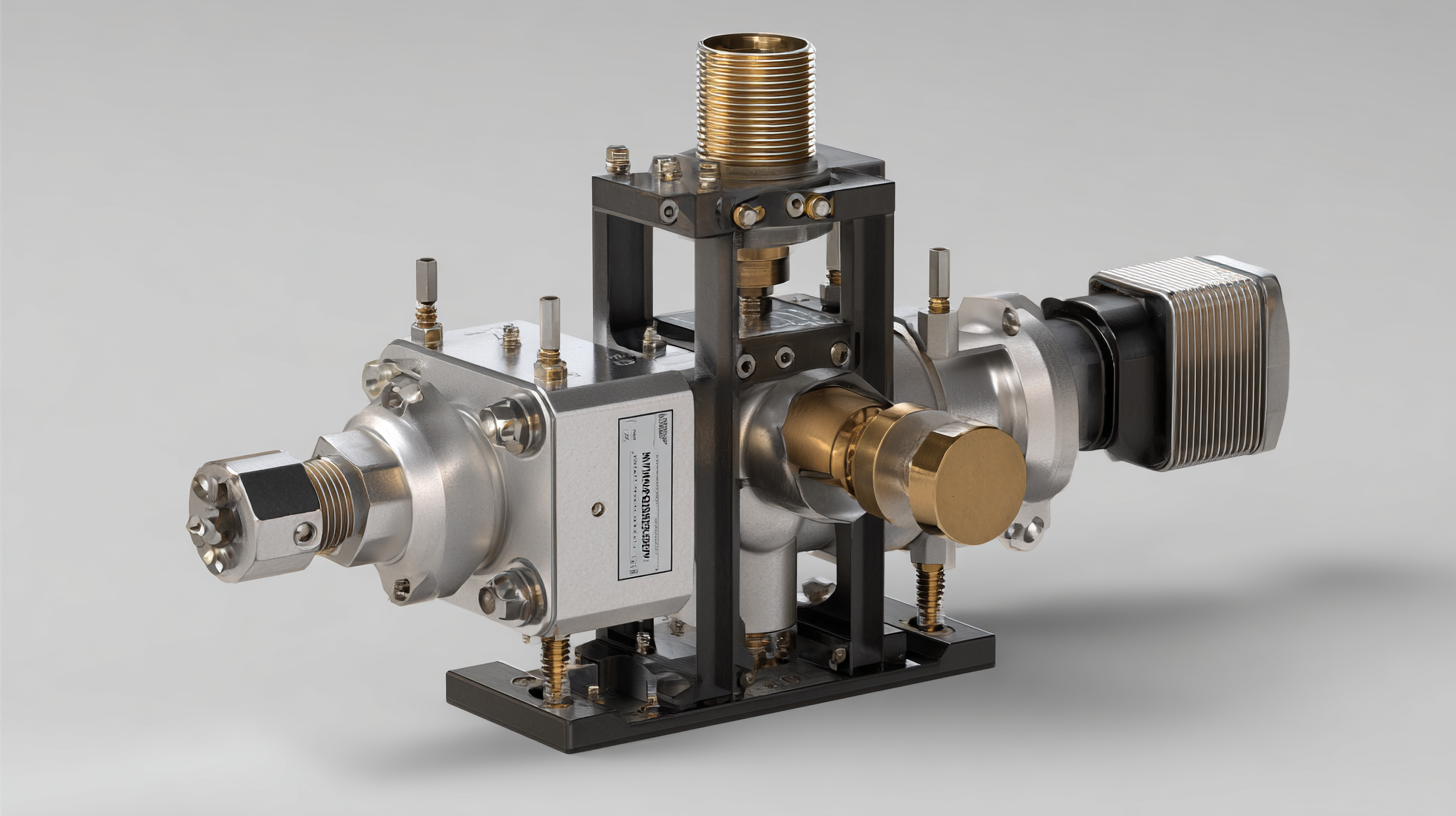

Pneumatic valve actuators have gained significant traction in various industrial applications due to their unmatched reliability and performance. When evaluating high-quality pneumatic valve actuators, several key features come into play. First and foremost, the design must ensure robust construction to withstand demanding operating conditions. A modular design not only simplifies installation and maintenance but also enhances the actuator's adaptability across different systems, embodying a user-friendly approach that manufacturers are increasingly adopting.

Another vital aspect is the responsiveness and precision of control that these actuators provide. Advanced technologies, including piezoelectric regulations, are being integrated to achieve superior performance. These innovations allow for highly accurate actuation, essential for operations that demand precise positioning, such as image-guided robotics. Furthermore, energy efficiency remains a paramount concern in modern manufacturing, pushing manufacturers to create pneumatic actuators that minimize both energy consumption and environmental impact, combining functionality with sustainability effectively.

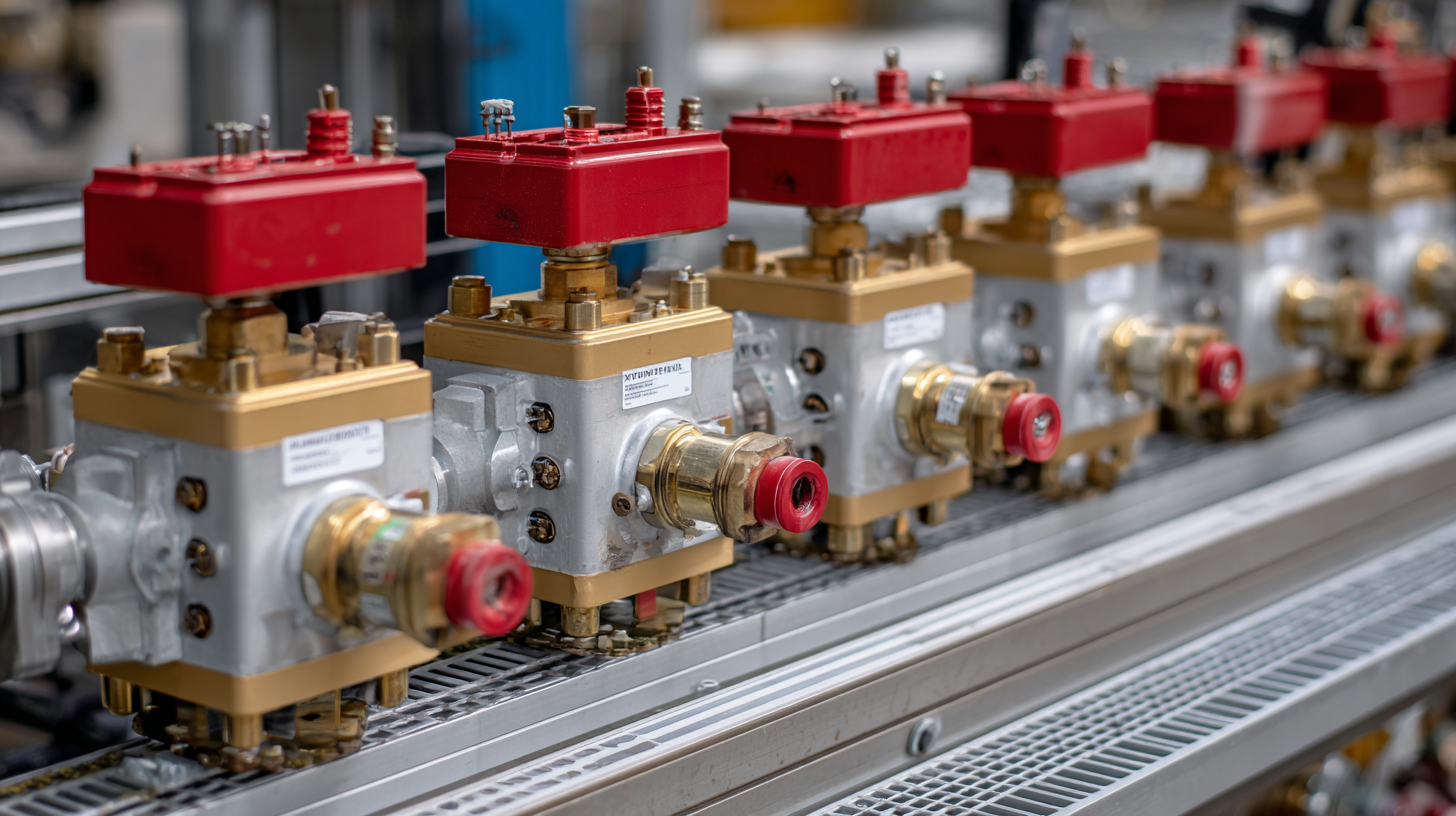

In the realm of pneumatic valve actuators, China's manufacturing standards stand as a benchmark for quality and innovation. The nation's extensive experience in engineering and production has led to the development of rigorous guidelines that ensure each actuator meets both domestic and international expectations. These standards encompass materials, design, and performance metrics, enabling manufacturers to create robust products that endure the rigors of diverse industrial applications.

Moreover, Chinese manufacturers invest heavily in technology and research, resulting in advancements that consistently push the envelope of efficiency and reliability. By adhering to global certifications and best practices such as ISO and CE, these manufacturers have built a reputation for delivering high-performance actuators that are trusted in markets worldwide. The combination of meticulous quality control and cutting-edge technology facilitates a level of precision that is unmatched, making China's pneumatic valve actuators a preferred choice for companies looking for dependability and excellence in performance.

In the context of evaluating supplier certifications and compliance with global standards, the importance of sustainability cannot be overstated. As manufacturers in China, particularly those producing pneumatic valve actuators, look to boost their international reputation, adherence to rigorous sustainability standards becomes imperative. Suppliers must now demonstrate commitment to environmental responsibility, which is increasingly scrutinized by global companies and regulatory bodies. Certifications related to sustainability, such as ISO standards, are not just a matter of compliance but a pathway to gain competitive advantages in international markets.

Furthermore, the conversation around sustainability is expanding beyond mere compliance; it’s about fostering ethical practices throughout the supply chain. For instance, tackling modern slavery in global supply chains has emerged as a vital concern, compelling companies to audit their suppliers thoroughly. By ensuring that all partners meet high standards of ethical production and environmental care, businesses can build a trustworthy and reputable supply chain network. This shift towards accountability is likely to influence purchasing decisions and strengthen long-term relationships between manufacturers and their global clients.

| Manufacturer | Product Model | Certification | Compliance Standards | Global Reach |

|---|---|---|---|---|

| Manufacturer A | Model X1 | ISO 9001 | CE, UL | North America, Europe |

| Manufacturer B | Model Y2 | ISO 14001 | ATEX, RoHS | Asia, Africa |

| Manufacturer C | Model Z3 | ISO 45001 | API, JIS | South America, Australia |

In today's competitive market, procurement professionals are increasingly faced with the critical decision of balancing cost against quality, particularly in the realm of pneumatic valve actuators. While it may be tempting to opt for the lowest bid, such a choice can often lead to long-term issues, including increased maintenance costs and performance failures. As highlighted by recent news, companies are embracing digital transformation and automation technologies to streamline their purchasing processes and ensure they source quality products while optimizing costs. This approach is essential for achieving sustainable growth and operational efficiency.

By leveraging data analytics and intelligent sourcing platforms, organizations can make well-informed decisions that prioritize quality alongside cost. As the market evolves, the importance of collaborating with trusted manufacturers who are committed to delivering high-quality actuators cannot be overstated. Not only does this strategy lower the risk of issues down the road, but it also enhances overall supply chain resilience, ultimately leading to improved profitability and competitive advantages in the marketplace.

In today's industrial landscape, the importance of building long-term relationships with trusted pneumatic actuator manufacturers cannot be overstated. As highlighted by industry leaders, trust is foundational in this sector. Peter Laube emphasizes that fostering strong, reliable partnerships can significantly enhance not only the quality of products but also the efficiency of operations. This notion is especially relevant when considering China's leading manufacturers of pneumatic valve actuators. Their commitment to quality and innovation makes them a dependable choice for companies worldwide.

When selecting a manufacturer, it's essential to assess their track record and reputation. Here are some tips for establishing a successful partnership:

First, prioritize communication. Regular discussions about needs and expectations help build transparency and mutual respect.

Second, invest time in visiting facilities and understanding their manufacturing processes. This will allow you to gauge their quality assurance practices and reliability.

Lastly, seek references from other companies that have collaborated with them. These insights can provide valuable information about their capabilities and performance level, ensuring that you make an informed decision.