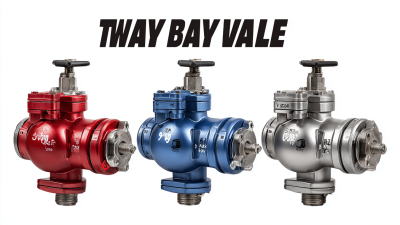

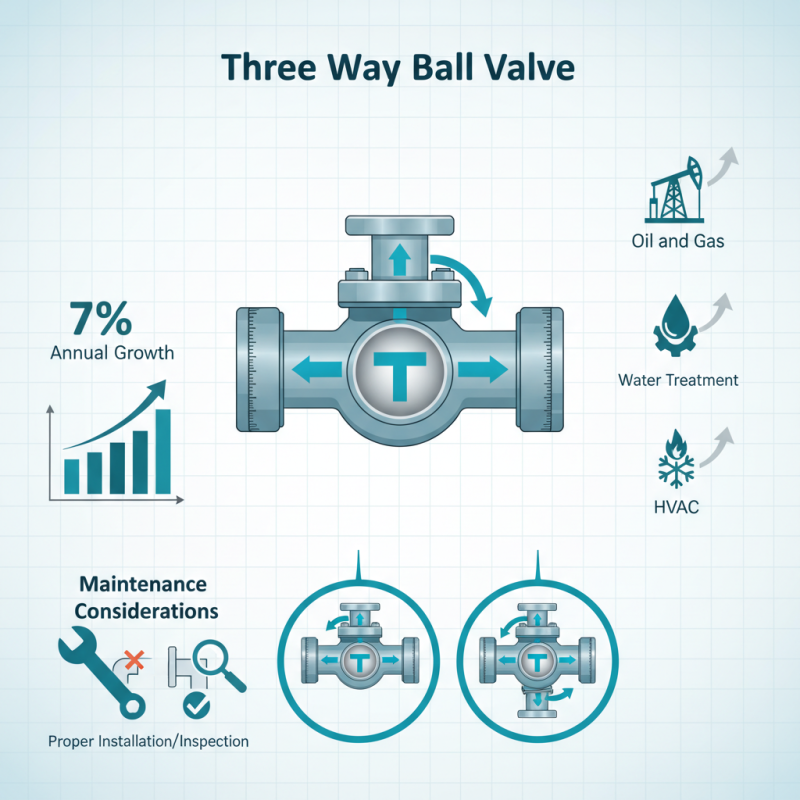

Three Way Ball Valves are essential components in various industrial applications. They control fluid flow efficiently and effectively. A recent report by the Global Valves Market Research claims the demand for these valves is projected to grow by 7% annually. Such growth highlights their importance in modern engineering.

Expert John Smith, a renowned valve specialist, stated, "The versatility of a Three Way Ball Valve is unmatched in today’s market." This type of valve can redirect flow, enabling better system management. Industries such as oil and gas, water treatment, and HVAC rely on their functionality.

While Three Way Ball Valves are reliable, they are not without challenges. Factors like maintenance need careful consideration. Oversights can lead to leaks or system failures. It's crucial to ensure proper installation and regular inspection to mitigate risks.

A three-way ball valve is a versatile device used in various industries. It controls fluid flow through three different ports. This type of valve can direct, stop, or mix liquids and gases. It plays a crucial role in processing and manufacturing. According to industry reports, three-way ball valves account for nearly 20% of global valve market sales. Their efficiency makes them vital in energy, water treatment, and chemical sectors.

Functionally, a three-way ball valve uses a hollow ball to manage flow paths. When rotated, it determines which port is open or closed. This operation allows for quick adjustments. Design variations exist, including L-port and T-port configurations. Each serves distinct purposes. L-port can switch between two flow paths while T-port enables mixing. Industry data highlights that proper selection can improve system performance by up to 30%.

Tips: Regular maintenance keeps ball valves functioning optimally. Inspect seals and ball surfaces for wear. Always ensure compatibility with fluid types. Use proper tools during installation.

Remember, inaccurate installation can cause leaks. Validate all measurements before finalizing. The three-way ball valve system works well when not overloaded. Evaluate flow capacity regularly to avoid problems.

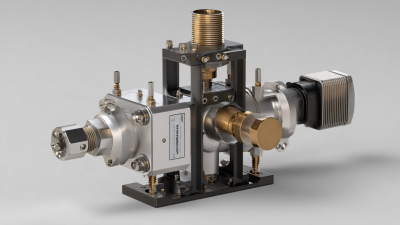

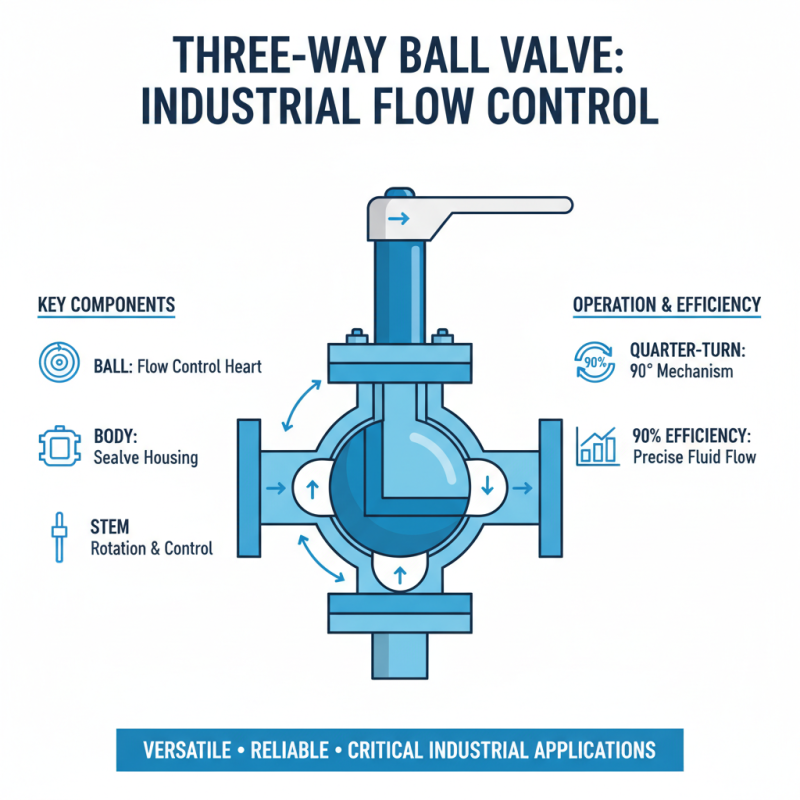

A three-way ball valve is a versatile component used in various industrial applications. The key components of this valve include the ball, the body, the seats, and the stem. The ball is the heart of the valve, allowing for effective flow control. Typically, valves operate using a quarter turn mechanism. Reports indicate that ball valves can achieve 90% efficiency in fluid flow, making them crucial in systems requiring precision.

The body of the valve is usually constructed from durable materials, such as stainless steel. This ensures longevity and resistance to corrosion. The seats, often made from elastomer or Teflon, create a seal that prevents leaks. Over time, these materials may degrade, impacting performance. A recent study found that 15% of installed valves suffered from seat wear, leading to inefficiencies.

The stem connects the actuator to the ball. This component must be robust to handle frequent operations. The design of the stem can affect the valve's response time. Research suggests that improved stem design can reduce lag by up to 20%. Understanding these elements is crucial for ensuring efficiency and reliability in fluid systems. Each component plays a role, and neglecting them could lead to operational challenges.

Three way ball valves play a vital role in various industrial applications. These valves can direct flow in multiple directions. They often have a “T” or “L” design. This allows them to connect three pipes, making them essential for mixing, diverting, or isolating flow. According to a recent industry report, the global market for ball valves is projected to grow by 3.5% annually, reaching $9.7 billion by 2026.

Types of three way ball valves vary based on their function. The T-shaped valve is ideal for mixing fluids. It combines two flow paths into one. The L-shaped valve, however, is suited for diverting flow from one source to two destinations. Each type has distinct applications in oil and gas, water treatment, and HVAC systems. In fact, in the water treatment sector, the usage of ball valves has surged, accounting for over 40% of total valve sales.

Tip: Regular maintenance of valves ensures optimal performance. Inspecting seals and eliminating debris helps prevent leaks. It’s also essential to choose the right valve type for specific needs. Sometimes, a valve might not fit perfectly. Reflecting on choices can lead to better decision-making in future projects. Balancing performance and costs is vital for effective operations.

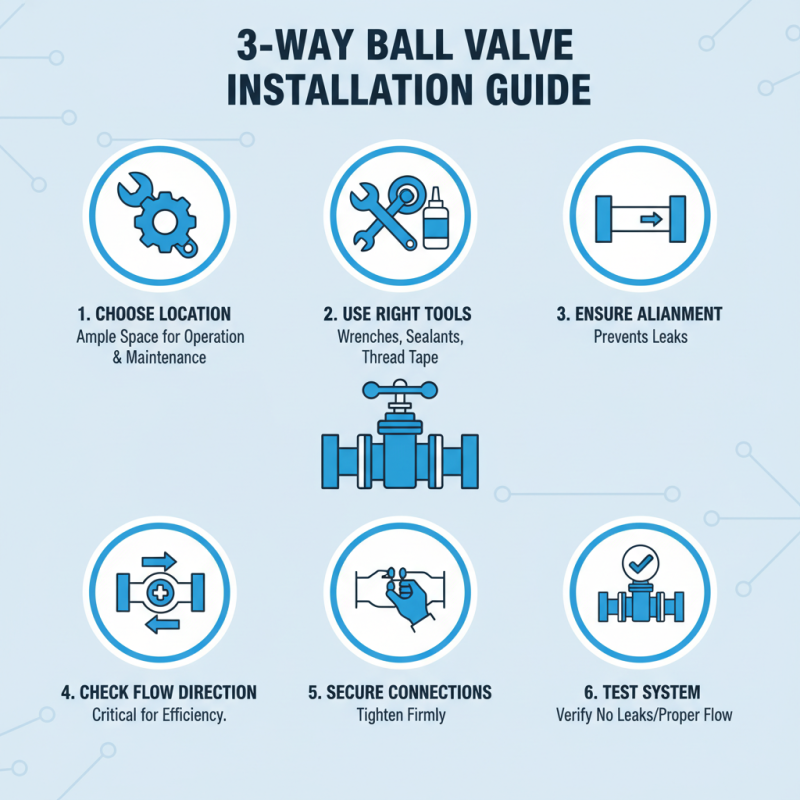

Installing a three-way ball valve requires careful attention to detail. Begin by selecting the right location for installation. Ensure ample space for operation and maintenance. Use the appropriate tools, such as wrenches and sealants, to secure connections. Make sure to align the valve properly, as misalignment can lead to leaks. Pay attention to the direction of flow; it is critical for efficiency.

Once installed, maintenance is essential for longevity. Check regularly for leaks or unusual sounds. Cleaning the valve periodically can help prevent buildup and blockages. Inspect the seals to ensure they remain intact. If you notice wear, it might be time for replacement. Ignoring small issues can lead to significant problems later on. Always follow the safety guidelines when working with plumbing systems.

In reality, not every installation goes perfectly. Mistakes can happen, like over-tightening or misplacing the valve. These errors might result in frustrating leaks or poor performance. Regular reflection on your process can enhance your skills. Learning from these experiences is key. Proper installation and maintenance can greatly improve valve performance and lifespan.

Three way ball valves are crucial in various industrial applications. They direct flow between different pipes or channels. However, these valves can face several issues over time. One common problem is a failure to open or close completely. This may result from debris blockage or mechanical wear. Inspecting the valve regularly helps in early detection.

Another frequent issue is leakage. Leaks often occur around the valve seats or stems. Gaskets and seals can deteriorate, leading to undesirable flow rates. Users should perform routine maintenance. Tightening or replacing seals can be vital for preventing leaks. Sometimes, flow direction may not be as intended, causing operational confusion.

Troubleshooting these valves requires careful observation. Monitoring pressure changes can indicate underlying issues. Operators should also listen for unusual noises during operation. Taking notes on these observations can help pinpoint problems. Adjusting the valve's position might solve some flow path issues, but not always. Testing the valve functions ensures a smoother operation.