In the increasingly complex landscape of industrial automation, selecting the appropriate ball valve actuator is crucial for optimizing system performance and reliability. According to a recent report from MarketsandMarkets, the global actuators market is projected to reach USD 63.7 billion by 2026, driven largely by advancements in smart technologies and the rising demand for process automation in various industries. With ball valve actuators playing a pivotal role in controlling the flow of fluids and gases, understanding how to choose the right actuator is essential for engineers and decision-makers. This blog will provide five expert tips that aim to simplify the selection process, ensuring that your application is equipped with the most efficient, cost-effective, and reliable ball valve actuator tailored to your specific needs.

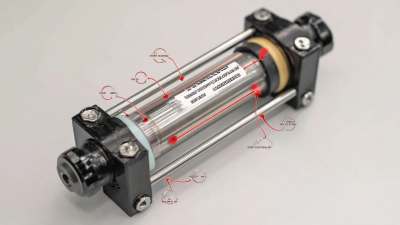

When selecting a ball valve actuator, understanding the different types available is crucial. Ball valve actuators generally fall into three categories: electric, pneumatic, and hydraulic. Electric actuators are renowned for their precision and ease of control, making them ideal for applications that require reliable operation without the need for complex piping. Pneumatic actuators, on the other hand, are favored for their quick response times and simplicity in installation, perfect for environments where speed and efficiency are paramount. Lastly, hydraulic actuators provide high torque and are often used in larger systems where heavy-duty performance is necessary.

When choosing the right actuator, consider the specific requirements of your application. For instance, if you are operating in a confined space, a compact electric actuator may be the best choice to maximize efficiency. Another tip is to assess the available power sources; make sure the actuator can be supported by your existing infrastructure. Additionally, always evaluate the actuator's compatibility with the valve types in use, as mismatches can lead to operational issues. By focusing on these elements, you can ensure that your selected actuator will effectively meet your operational needs.

| Actuator Type | Power Source | Control Type | Operating Range | Applications |

|---|---|---|---|---|

| Electric Actuator | Electric | On/Off | 0-100% Open | Water Treatment |

| Pneumatic Actuator | Compressed Air | Modulating | 0-90% Open | Oil & Gas |

| Hydraulic Actuator | Hydraulic Fluid | On/Off | 0-100% Open | Heavy Machinery |

| Manual Actuator | Manual | On/Off | On-Demand | HVAC Systems |

When selecting a ball valve actuator, evaluating performance is paramount to ensuring you choose the right alternative for your specific applications. One key feature to consider is the actuator's torque output, which directly affects its ability to open and close valves under varying pressures. Look for actuators that provide sufficient torque to handle the maximum operating conditions of your system. Additionally, consider the speed of operation; some processes require quick actuation to prevent downtime or maintain system balance, so opting for an actuator with adjustable speed settings can enhance efficiency.

Another critical aspect is the type of control offered by the actuator. For precise performance, choose models that offer either electric or pneumatic controls, depending on your operational needs. Electric actuators tend to provide better accuracy and can be integrated into automated systems. On the other hand, pneumatic actuators are often favored in environments where rapid response times are essential. Lastly, don’t overlook the importance of environmental resistance features; if your actuator will be placed in harsh conditions, ensure it is rated for durability against factors like temperature extremes, humidity, and corrosive substances.

When selecting the right ball valve actuator, it's crucial to weigh the benefits of electric and pneumatic options. Electric actuators are increasingly in demand, projected to reach significant growth by 2032, driven by the need for precision and control in numerous industries, including oil and gas, energy, and wastewater management. Their ability to operate efficiently under various conditions makes them an appealing choice for many applications.

On the other hand, pneumatic actuators offer rapid operation and are often more suited for environments where high-speed actuation is required. In certain sectors, such as aerospace and defense, the reliability and quick response times of pneumatic systems can be a deciding factor for engineers. According to recent market analysis, the pneumatic actuator sector continues to maintain a strong position alongside electric systems, with a balanced growth trajectory influenced by differing industry needs. Thus, the choice between electric and pneumatic ball valve actuators should be guided by specific operational requirements, environmental conditions, and long-term maintenance considerations.

When selecting a ball valve actuator, finding the right balance between cost and efficiency is crucial. With the energy consumption of HVAC systems accounting for nearly 40% of global energy use, optimizing valve performance can significantly impact overall building efficiency. Recent studies indicate that dynamic hydronic balancing can reduce HVAC energy consumption by up to 30%, showcasing the importance of selecting a cost-efficient actuator that meets operational demands.

Tip 1: Consider flow requirements and operational scenarios. Matching an actuator to the specific flow needs of a system can lead to enhanced performance and longer lifespan, ensuring that you achieve the desired efficiency without incurring unnecessary costs.

Tip 2: Evaluate the actuator's adaptability to changing conditions. For example, systems with dynamic balancing require actuators that can quickly respond to fluctuations, thus maintaining optimal performance. Choosing an actuator with robust feedback mechanisms can minimize energy waste and improve power quality, ultimately benefiting your bottom line.

When considering ball valve actuators, many might be swayed by common misconceptions surrounding alternatives. One frequent misunderstanding is that electric actuators offer better performance than pneumatic ones in all situations. While electric actuators can provide precise control over valve positions, they may not perform optimally in environments with extreme temperatures or in situations where rapid actuation is necessary. Pneumatic actuators, on the other hand, excel in high-speed operations and can function well under harsh conditions, making them a suitable choice for many industrial applications.

Another misconception is that manual operation is always less reliable than automated solutions. While automation does bring efficiency and consistency, there are scenarios where manual operation is preferable due to simplicity and lower initial costs. In smaller systems or where budget constraints exist, manual valve operation can be more effective and just as reliable, depending on the specific needs of the operation. Understanding these differences can help industries make informed decisions, tailored to their unique operational requirements.

This bar chart illustrates the common use cases for different types of ball valve actuators. Pneumatic and Electric actuators are predominantly used, while Manual actuators find limited application in specific scenarios.