In today's industrial landscape, the efficiency and reliability of systems hinge significantly on the effectiveness of actuator valves. According to a recent report by Markets and Markets, the global actuator market is projected to reach $36.57 billion by 2025, growing at a CAGR of 6.9%. This statistic underscores the increasing reliance on actuator valve solutions across various sectors, including oil and gas, water treatment, and manufacturing. As organizations strive to enhance operational performance and reduce downtime, optimizing actuator valve selection and implementation becomes paramount. This guide provides a comprehensive checklist for identifying the best actuator valve solutions tailored to specific applications, ensuring that you achieve optimal performance, energy efficiency, and long-term reliability in your operations. By taking a strategic approach to actuator valve optimization, businesses can not only improve productivity but also drive down operational costs in an increasingly competitive market.

When it comes to enhancing performance optimization in industrial applications, the choice of actuator valve solutions plays a crucial role. Various types of actuator valves are available, each tailored to meet specific operational requirements.

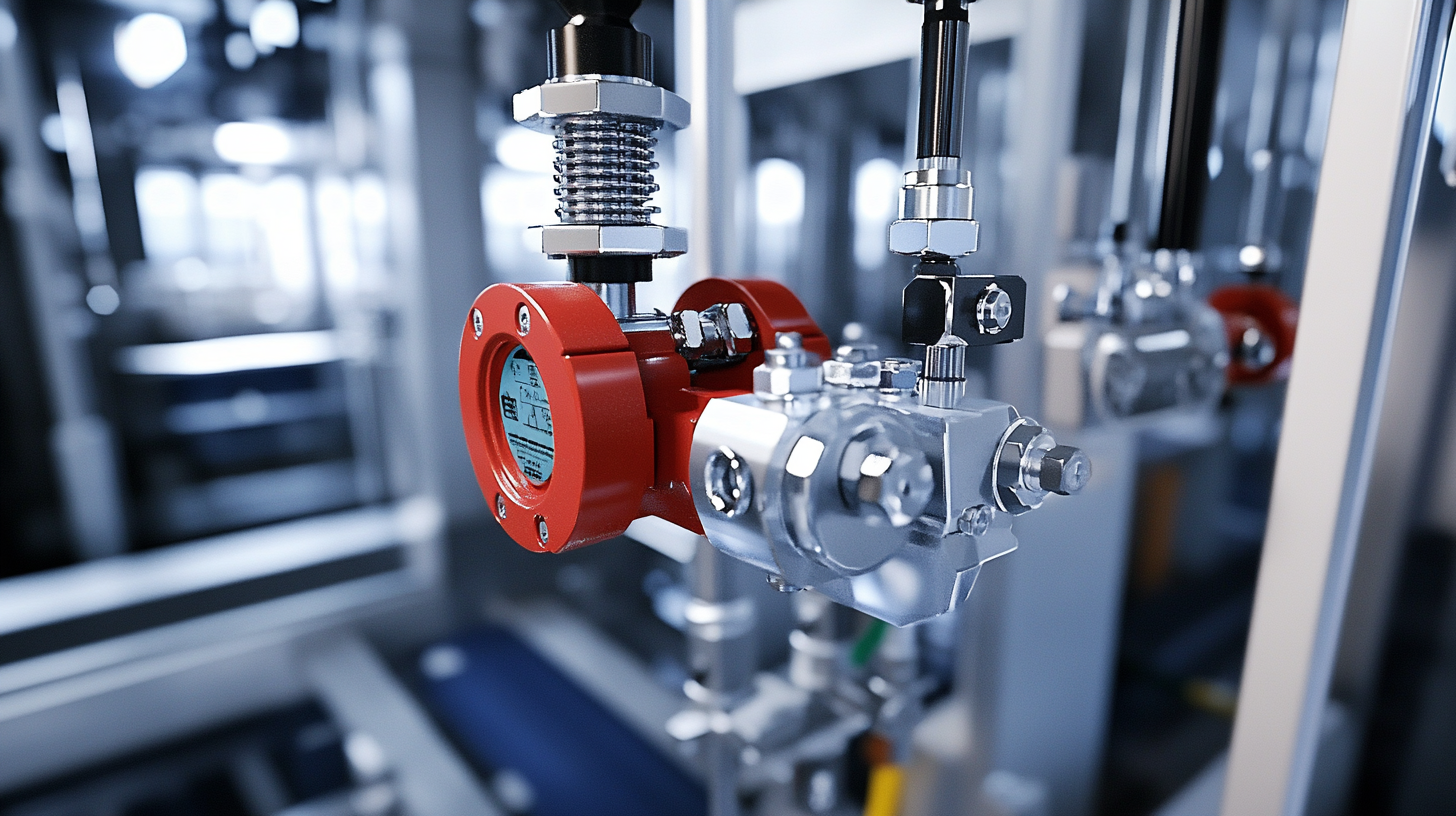

Pneumatic actuators, for instance, utilize compressed air to drive the valve mechanism, allowing for rapid response times and effective control in systems requiring swift adjustments. These valves are ideal for industries such as food processing, where hygiene and speed are paramount.

When it comes to enhancing performance optimization in industrial applications, the choice of actuator valve solutions plays a crucial role. Various types of actuator valves are available, each tailored to meet specific operational requirements.

Pneumatic actuators, for instance, utilize compressed air to drive the valve mechanism, allowing for rapid response times and effective control in systems requiring swift adjustments. These valves are ideal for industries such as food processing, where hygiene and speed are paramount.

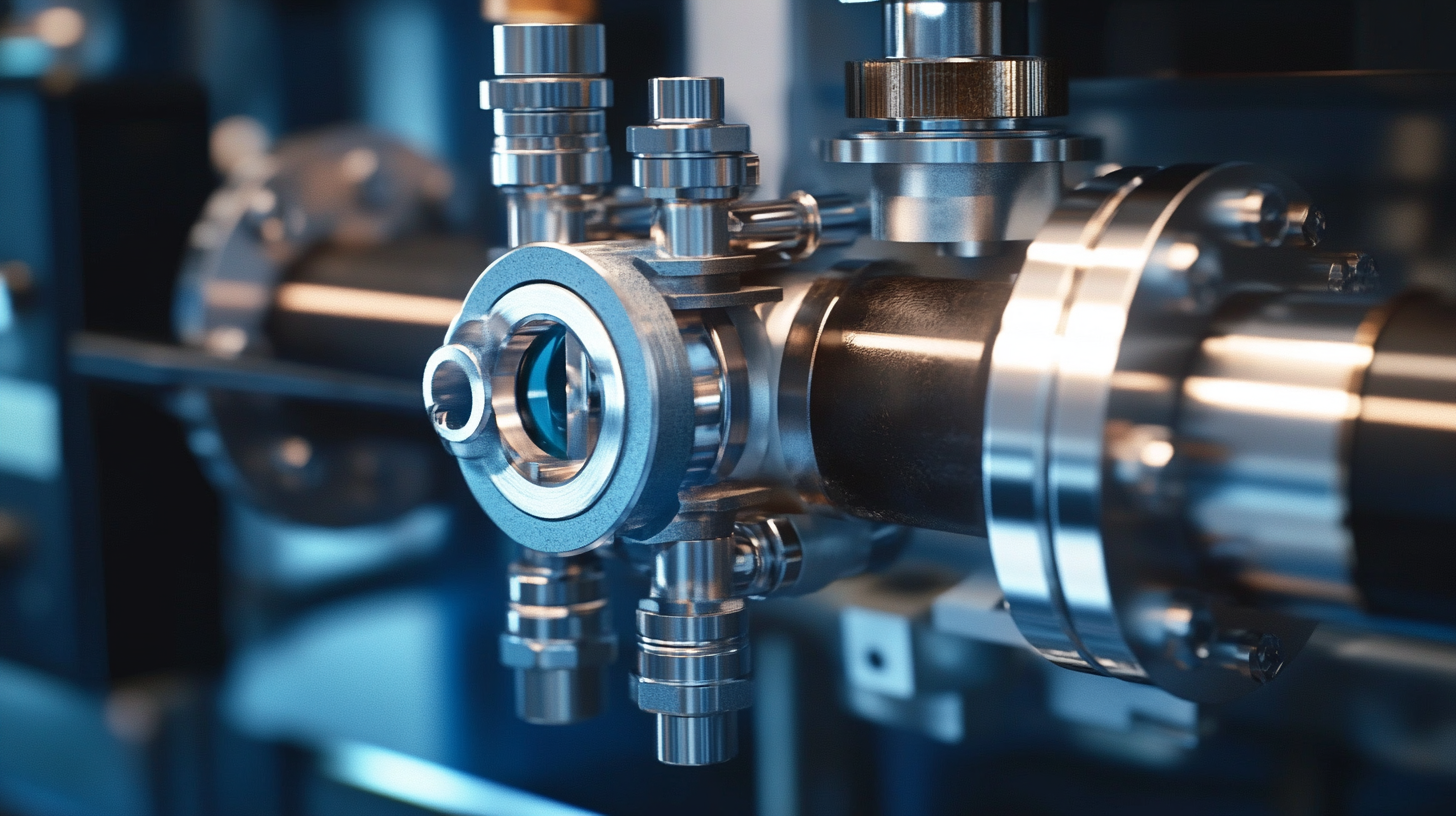

Electric actuators, another popular choice, offer precise control and the ability to integrate with modern automated systems. They are typically used in environments where power supply is stable and control accuracy is vital, such as in chemical processing plants. Additionally, hydraulic actuators are favored for their high force output, making them suitable for larger valve applications that demand significant torque. By understanding the distinct features and benefits of each type of actuator valve, businesses can make informed decisions that lead to enhanced efficiency and productivity in their operations.

Electric actuator valves are pivotal in modern automation systems, offering distinct advantages that enhance operational efficiency. One of the key features of these valves is their precise control capabilities. With the ability to modulate flow rates with pinpoint accuracy, electric actuators ensure that processes maintain optimal performance levels, reducing energy consumption and minimizing waste. This precision is especially critical in industries such as chemicals and pharmaceuticals, where exact fluid handling is essential.

Another significant advantage of electric actuator valves is their integration with digital control systems. This feature allows for seamless communication and real-time monitoring, enabling operators to analyze performance data and swiftly adjust parameters as needed. Additionally, electric actuators are known for their rapid response times, which can significantly improve the reaction time in critical applications like emergency shut-off scenarios. Their applications extend to a variety of sectors, including water treatment, HVAC systems, and food processing, where reliability and efficiency are paramount. The versatility and features inherent in electric actuator valves make them a preferred choice for many industrial applications.

Pneumatic actuator valves have emerged as a crucial component in various industrial applications, showcasing distinct advantages over traditional systems. One of the primary benefits of pneumatic actuator valves is their responsiveness and speed. With the ability to operate at pressures exceeding 100 psi, they can facilitate quick adjustments in flow control, making them ideal for dynamic processes in fields like food and beverage manufacturing. According to a report by the International Society of Automation, pneumatic systems can improve cycle times by up to 30%, significantly enhancing productivity.

Furthermore, the application scenarios for pneumatic actuator valves are diverse. In bioprocessing operations, the single-use diaphragm valve exemplifies the trend toward automated systems that ensure process reliability. This is particularly significant in industries that prioritize hygiene and sterility, as single-use valves minimize contamination risks.

Additionally, the integration of pneumatic actuation in soft robotics reveals innovative approaches to assistive technologies. Such systems, including soft pneumatic exoskeletons, have been shown to reduce muscle activity and metabolic costs by 20%, thereby enhancing user comfort and efficiency in material handling tasks. The versatility and efficiency of pneumatic actuator valves underscore their vital role in modern industrial solutions.

In the evolving landscape of industrial applications, hydraulic actuators play a crucial role, particularly in sectors demanding high reliability and power, such as aerospace and defense. These actuators are integral in providing the necessary force for controlling mechanisms in challenging environments. The military actuators market is projected to expand significantly; reports indicate that the market size is expected to reach substantial figures by 2030. This growth underscores the ongoing demand for advanced hydraulic systems, particularly in military applications where efficiency and response time are critical.

The trend towards electrical actuators is also gaining traction in the aerospace and defense sectors. Unlike traditional hydraulic systems, electrical actuators offer enhanced precision and reduced maintenance needs, making them a favorable choice for many applications. Analysts highlight that the shift towards these technologies is influenced by their capacity to deliver significant energy savings while meeting stringent performance standards. As industries increasingly prioritize sustainability and performance, the integration of both hydraulic and electrical actuator technologies will likely redefine operational efficiencies in disaster response, further facilitating the deployment of sophisticated robotics in critical situations.

When selecting the right actuator valve for specific applications, understanding the varied types and their performance characteristics is vital. A recent report by the Valve Manufacturers Association of America indicates that the global market for actuator valves is expected to grow at a CAGR of 5.7% from 2021 to 2027. Given this growth, choosing the right actuator valve can significantly impact operational efficiency and cost-effectiveness.

Actuator valves come in several configurations, including pneumatic, electric, and hydraulic variants. Each type offers distinct advantages: pneumatic actuators are known for their speed and reliability, while electric actuators provide enhanced control and energy efficiency. A study conducted by ResearchAndMarkets highlights that electric actuators are increasingly favored in industries like oil and gas, where precision and low maintenance are critical, accounting for approximately 30% of the actuator valve market share in 2022. Conversely, pneumatic options remain popular in sectors requiring high-speed operations, demonstrating a continued stronghold in applications like manufacturing and food processing.

Ultimately, the selection of actuator valves should hinge on a comparative analysis of specific needs, considering factors such as operating environment, maintenance requirements, and energy consumption. By evaluating these aspects against industry data, businesses can make informed decisions that optimize performance and operational productivity.