In the competitive world of manufacturing, efficient processes are crucial. One of the key methods is the use of a Plastic Injection Mold. Adrian Smith, an expert in the field, once stated, "A well-designed mold can significantly reduce production time and costs." This highlights the importance of precision in mold design.

Plastic Injection Molding is not just about speed. It's also about quality. Every detail in the mold affects the final product. Shoddy craftsmanship can lead to flaws. These flaws might require costly rework, wasting both time and resources. Manufacturers must be aware of potential pitfalls in the process.

While the technology is advanced, challenges still remain. The process requires constant monitoring and adjustments. A mold might function well initially. However, over time, wear and tear can create issues. Reflection on these experiences can lead to improved strategies. Therefore, understanding the nuances of Plastic Injection Mold is vital for success in manufacturing.

Plastic injection molding is a key technology in manufacturing. It allows for the efficient production of complex plastic parts. In 2020, the global plastic injection molding market was valued at around $255 billion. This figure is expected to grow at a CAGR of 5.6% from 2021 to 2028. The process is widely used across various industries, including automotive, consumer goods, and medical devices.

Understanding the basics is crucial. The process involves injecting molten plastic into a mold, where it cools and solidifies. Factors like temperature, pressure, and cooling time significantly affect product quality. For instance, inappropriate cooling can lead to warping or dimensional issues. A study by Technavio highlighted that nearly 30% of manufacturers face challenges in mold design and maintenance. This can result in waste and increased production costs, highlighting the need for better practices.

Sustainability is becoming a pressing concern in the industry. Traditional processes often produce significant waste. Newer methods aim to reduce scrap and improve energy efficiency. The use of recycled materials is gaining traction. However, this shift requires significant investment in machinery and training. Balancing cost and sustainability remains a challenge for many businesses.

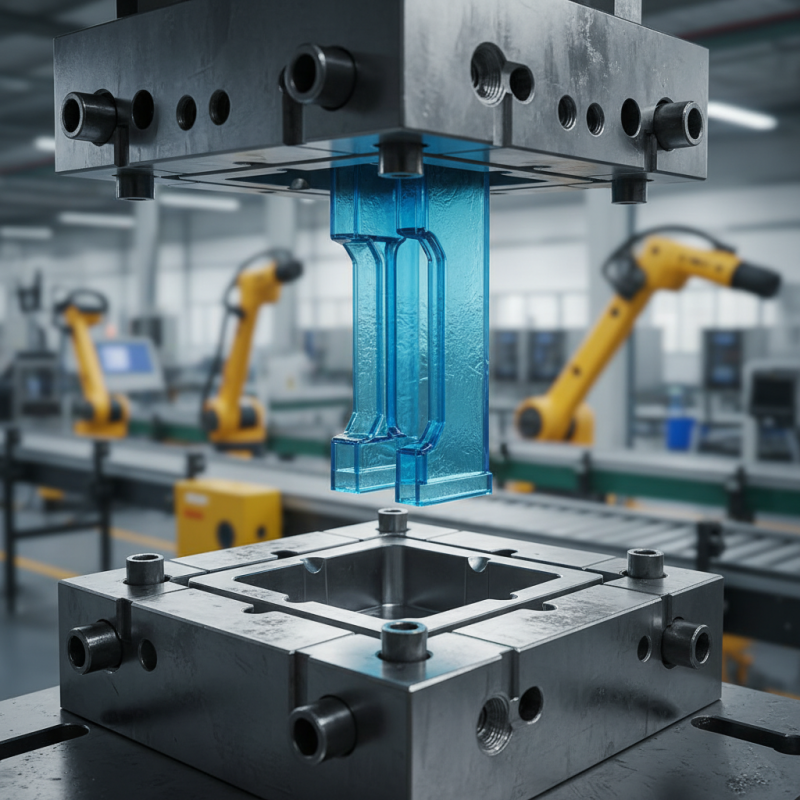

Plastic injection molds play a crucial role in manufacturing. Understanding their key components can significantly enhance production efficiency. The core elements include the mold base, cavity, core, ejector system, and cooling channels. Each component contributes to the mold's performance and affects overall output.

The mold base provides the structure. It must be robust to endure high pressure during injection. The cavity and core shape the plastic, creating the final product. An efficient cooling system reduces cycle time, allowing molds to cool faster and improve production rate. Studies show that optimizing cooling channels can reduce cycle times by up to 25%.

Tips: Maintain molds regularly. Small dents or wear can degrade performance. Regular inspections help catch potential issues.

The ejector system facilitates the part removal process. A strong ejector can reduce damage risks as the finished product exits. Not all molds are created equal. Some may experience inconsistent results due to design flaws. It's essential to reflect on design choices and seek improvements continually. Each innovation presents an opportunity for better outcomes.

| Component | Function | Material | Common Issues |

|---|---|---|---|

| Mold Base | Provides structural support for the mold | Steel, Aluminum | Warping, Corrosion |

| Cavities | Holds the shape of the part being produced | Hardened Steel, Beryllium Copper | Wear and Tear, Dimensional Inaccuracy |

| Ejector System | Facilitates removal of the molded part from the cavity | Steel | Jamming, Misalignment |

| Cooling Channels | Regulates temperature to enhance cycle efficiency | Steel, Copper | Blockage, Uneven Cooling |

| Injection System | Delivers molten plastic into the mold cavities | Steel | Leakage, Pressure Issues |

Plastic injection molding is a widely used manufacturing process. It allows for efficient production of various plastic parts. Here’s a simple step-by-step process for effective use.

To start, create a design for the part to be molded. Use CAD software to draft the blueprint. Once the design is finalized, make the injection mold. The mold needs to be precise. Any flaw can lead to a defective product.

Next, select the right plastic material. Different materials have different properties. Choose one that fits the product's requirements.

Once the mold is ready and the material is chosen, set up the injection molding machine. Melt the plastic and inject it into the mold. Monitor temperature and pressure closely. Small errors can affect quality. After the plastic cools, remove the part from the mold. Inspect it for any imperfections or inconsistencies.

Tips: Always review the design thoroughly before proceeding. It saves time in the long run. Consider prototyping the part to identify potential issues early. Regular maintenance of the injection machine is crucial. It helps maintain quality and efficiency in production.

Optimizing production efficiency in plastic injection molding requires a focused approach. Advanced techniques can significantly enhance output while reducing waste. One effective method is to utilize the right materials. Choosing the best resin impacts quality and production speed. This choice often involves testing different types to find the optimum fit.

Monitoring the injection process is crucial. Adjusting parameters like temperature and pressure can lead to better results. A slight change might improve cycle times or product integrity. But adjustments can also cause defects if not carefully managed. This balancing act is essential and demands constant evaluation.

Training the workforce plays a pivotal role. Skilled operators can identify issues quickly. Regular training helps in understanding complex machinery. Yet, even seasoned workers may overlook small details. Keeping an open dialogue about potential improvements can foster a culture of continuous enhancement. Emphasizing meticulousness in every stage can lead to significant gains in efficiency.

Plastic injection molding is a powerful manufacturing process. However, it comes with common challenges. Understanding these issues can greatly enhance efficiency.

One major challenge is air traps. They can lead to defects in the final product. Air gets trapped in the mold, causing weak spots. To tackle this, improve venting in the mold design. Ensure there are proper escape routes for air. This small adjustment can significantly reduce defects.

Another issue is material flow. If the material doesn’t fill the mold evenly, it results in uneven parts. This can happen due to temperature fluctuations. Maintain consistent heat levels during the process. Regular checks can help to spot temperature drops before they affect production.

These challenges highlight areas for growth. There’s always room for improvement. By focusing on mold design and process control, manufacturers can produce better quality parts more efficiently.